Hydraulic Components for Mechanical Seals

The Right Solution for Every Application

Product Details

- EKATO hydraulic components and sealing systems from one single supplier

- The sealing technology and hydraulic components were specially developed for agitators

- Precisely adapted to every application

- The best solution for any special sealing problem

- Individual hydraulics tailored to customer requirements

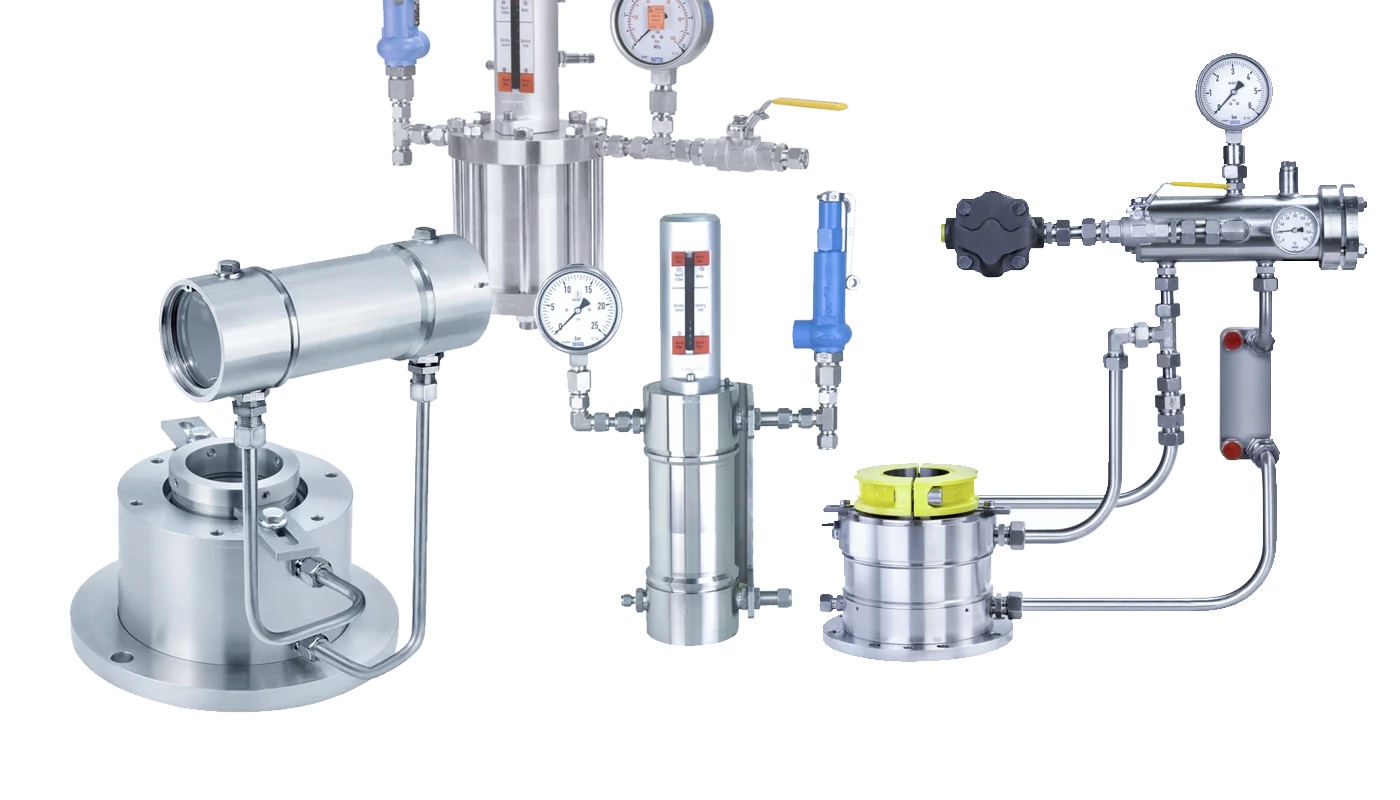

Storage Vessels

Storage Vvessel VG

- Storage vessel for seal liquid with side windows

- Contents 1.5 l

- Cooling of the seal liquid by cooling jacket (water jacket)

- Application up to 10 bar (abs)

Storage vessel VGS

- Storage vessel for seal liquid with float magnetic switch and level indicator for monitoring of the fill level

- Contents 1.5 l

- Application up to 10 bar (abs)

- Installation of a level limit switch (Liquiphant) for redundant monitoring in ATEX Zone 0

Storage vessel VGL

- Large storage vessel for seal liquid with float magnetic switch and level indicator for monitoring of the fill level

- Contents 6 l

- Cooling of the barrier liquid by integrated cooling coil

- Application up to 16 bar (abs)

Accessories for storage vessels

- Hand pump for refilling the seal liquid

- Pressure gauge and safety valve for pressure overlay

- Water jacket or cooling coil for cooling of the seal liquid

- Magnetic float switch with min–min alarm and switch amplifiers for ATEX Zone 1

- Level switch for redundant monitoring at ATEX Zone 0

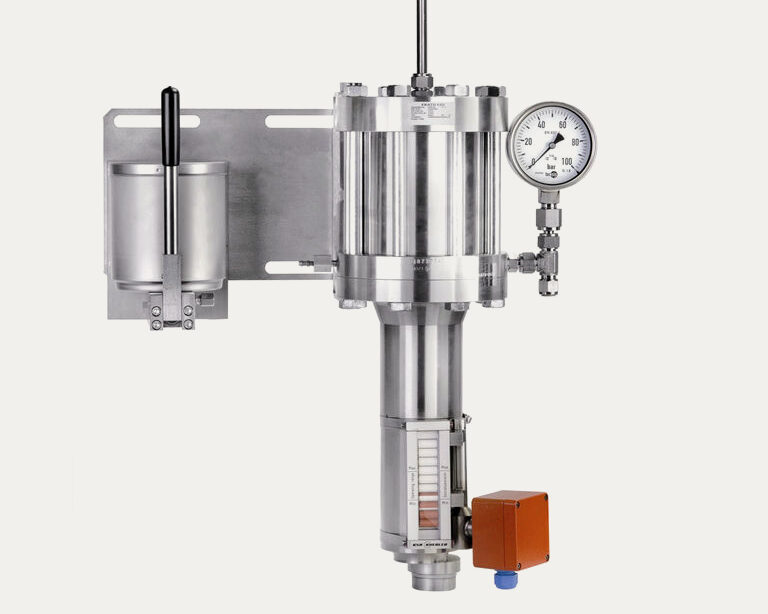

Pressure Compensators

Pressure compensator VGD

- With storage vessel including manometer and safety valve

- Cooling of the barrier liquid by cooling jacket (water jacket)

- Application up to 40 bar (abs) - Volumes 0.3 l

- Monitoring of the level via proximity switch – ATEX Zone 1

Pressure compensator VD 120

- For high pressure seals

- Application up to 70 bar (abs) - Volumes 0.8 l

- In combination with VD120PS pressure splitter, can be used up to 100 bar

- Proximity switch for monitoring the fill level

High pressure compensator VDH

- Installation of "overhead" for automatic ventilation

- Volume 0.8 l

- Magnetic roller display for fill level monitoring and automatic refilling

- Application up to 100 bar (abs)

Sterile System

Special requirements for mechanical seals occur in the operation of sterile processes, such as food processing, in the pharmaceutical industry and in the biotechnology. Therefore EKATO offers a complete sterile system consisting of a mechanical seal and a sterile installation.

These sterile systems are used when the vessel / process needs be sealed from any biomass by the mechanical seal.

The EKATO sterile system is an ideal solution for the process demand of a hot and completely sterile seal liquid, where biomass can not grow. On the other hand it serves the mechanical seal demand of cool seal liquid for seal face lubrication and cooling.

VIDEO: EKATO Sterile System for mechanical seals

Functional description of the sterile system

Step 1: Flow-through sterilization

Cleaning and sterilization of all parts with fresh steam during standstill of the agitator

Step 2: System-filling

Filling the system with sterile condensate during standstill of the agitator

Step 3: Continuous loop-operation

Cyclical sterilization of the condensate by fresh steam and seal liquid condensate cooling by the heat exchanger during operation

Features – sterile system

- Complete sterile system, mechanical seal and sterile installation out one hand (less interfaces)

- Self regulating system with very low energy consumption

- Optimized mechanical seal design without gaps (ESD34S / ESD44S)

- Sterile conditions in the storage vessel during operation: no microbe growth

- Constant circulation and continuous sterilization of the condensate

- Overpressurized system due to steam pressure: no entry of extern contaminations

- Sterilization of the condensate after exiting the seal by inflowing fresh steam

- Sealing liquid condensate cooled by plate heat exchanger

- Sealing liquid condensate with ideal operating temperature: extended seal lifetime