EKATO

聚合

敏感工艺的现代混合解决方案

在聚合领域,EKATO 专注于混合技术解决方案的联合开发和放大。 这是通过使用现代混合技术优化现有聚合工艺的补充。 范围从“世界级”产品(如 HDPE、PET、PP 或 PVC)到特种产品以及生物基和可生物降解聚合物。

目录

乳液聚合

在乳液聚合中,水不溶性单体预分散在水相中。 与珠粒聚合相反,分散体不是通过湍流物理稳定,而是使用乳化剂化学稳定。 聚合不发生在直径为10-1000μm的分散的单体液滴中,而是在直径为约0.3-0.8μm的小得多的胶乳颗粒中发生。 它们含有聚合物和单体分子,并被乳化剂分子包围,乳化剂分子使它们相对于水相稳定。 由于粒径小,反应热可以很容易地消散到水相中。 由于乳液的低粘度和水的高导热性,容器壁和水相之间的传热非常好。

溶剂聚合

在均相溶剂聚合中,通过添加化学惰性溶剂降低粘度。 在整个过程中单体和聚合物都存在于溶液中。 在许多情况下,通过煮沸溶剂引起的同时蒸发冷却来改善除热。

悬浮聚合

有两种不同类型的悬浮聚合

- 成珠聚合:聚合物和单体都不溶于载液,因此聚合发生在单体液滴(直径 10-1000 μm)内。

- 沉淀聚合:单体溶解在载液中,而聚合物不溶,因此在聚合过程中沉淀。

初级聚合物颗粒的直径通常约为 1微米。 这些颗粒聚集成直径为 100-200 μm 的多孔二级颗粒。 固体颗粒在某些聚合阶段有粘在一起(凝结)的趋势,因此必须在流场中通过剪切力再次分离。

HIPS 高抗冲聚苯乙烯

生产高抗冲聚苯乙烯(HIPS)的设备通常由三至五个反应器的级联组成,分为预聚合和后聚合阶段。 在预聚合阶段,目标形态和粒度已基本预定义。 反应通常在100-150℃下进行,产率高达15-30%。 在后聚合期间,继续聚合反应以获得更高的产率和相应更高的粘度。 后聚合通常在140-190℃的温度下进行。

在反应器级联中,通过蒸发苯乙烯单体除去聚合热。 然后将气态单体冷凝并送回反应器。 这种类型的散热需要高均匀性和良好的表面夹带。 出于这个原因,这些反应堆通常配备有Ekato Paravisc。 温度均匀性是影响分子量分布的关键变量,因此影响可达到的产品质量。

橡胶

聚丁二烯(丁基橡胶)

聚丁二烯(丁基橡胶)用作合成橡胶,特别是用于汽车轮胎的胎面。 它几乎完全由使用齐格勒 – 纳塔催化剂的溶液聚合制备。 甲苯是最常用的溶剂。

反应的混合要求是良好的均质化和轴向流动,以确保浓度和温度梯度的快速均衡。

IIR(异丁烯 - 异戊二烯橡胶)

异丁烯 - 异戊二烯橡胶(IIR)是异丁烯和异戊二烯的共聚物。 该材料用于高性能长途汽车轮胎。

为了获得高分子量,必须在低至-90°C至-100°C的极低温度下小心控制强放热反应。 最常用的合成IIR的方法是低温阳离子聚合。

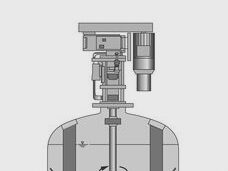

这种类型的聚合包括在氯甲烷中产生非常细的橡胶颗粒的悬浮液。 因为反应是非常放热的,所以反应器设计成具有非常高的轴向流速的引流管。 反应器的圆柱形腔室配备有管束式热交换器。 此外,极快的反应需要快速均质化进料。 叶轮从下方引入,这需要相应的浸没式密封和冲洗装置。

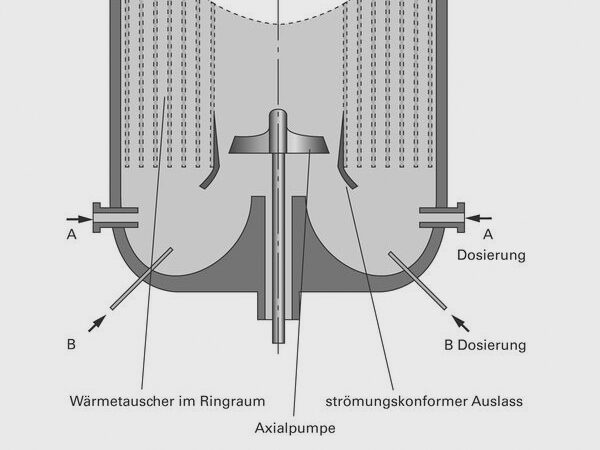

聚酯和PET(聚乙烯对苯二甲酸酯)

通过多官能羧酸与多官能醇的缩聚(或缩聚)合成PPolyesters。与其他经典聚合反应相比,其中水总是产物的缩聚是吸热的。将可逆反应的化学平衡转移到聚酯侧需要从反应混合物中连续除去由缩合反应产生的水。在高粘度下,水只能通过从反应混合物表面蒸发除去。这意味着必须使用具有小壁间隙的轴向泵送叶轮有效地循环反应器的内容物以实现高聚合度。尽管纯径向泵送搅拌器仅在靠近表面处产生高聚合度,但如果还存在轴向交换,则可在整个反应容器中实现。通过使用引流管可以显着改善轴向流动。

热塑性聚酯,特别是聚对苯二甲酸乙二醇酯,是用于制造纤维和瓶子的经济上重要的材料。一组缩聚物,即聚碳酸酯,作为高性能塑料越来越重要。

HDPE ( 高密度聚乙烯 )

HDPE的沉淀聚合在高压釜中在低压下进行。单峰HDPE在并联反应器中生产,而双峰HDPE在串联反应器中生产。目前的反应堆容积高达300立方米,容量高达500千吨/年。

催化剂在容器中分批制备,在另一容器中稀释,然后加入反应器中。连续操作的反应器也加入单体,氢和己烷。放热反应在5-10巴的压力和75-85℃的温度下进行。用外部热交换器除去热量。通过调节催化剂和共聚单体的类型和浓度以及氢的量来控制产物的分子量,分子量分布和密度。

加工链以后反应器结束,其中单体的转化率达到99%。将得到的悬浮液加入接收器中,然后离心,在流化床中用热氮气干燥,最后过筛。在挤出之前将稳定剂和添加剂混合。

由于这些聚合反应器的高形状,主要的混合任务是实现非常短的混合时间。此外,高壁速度必须防止容器壁上的结垢。

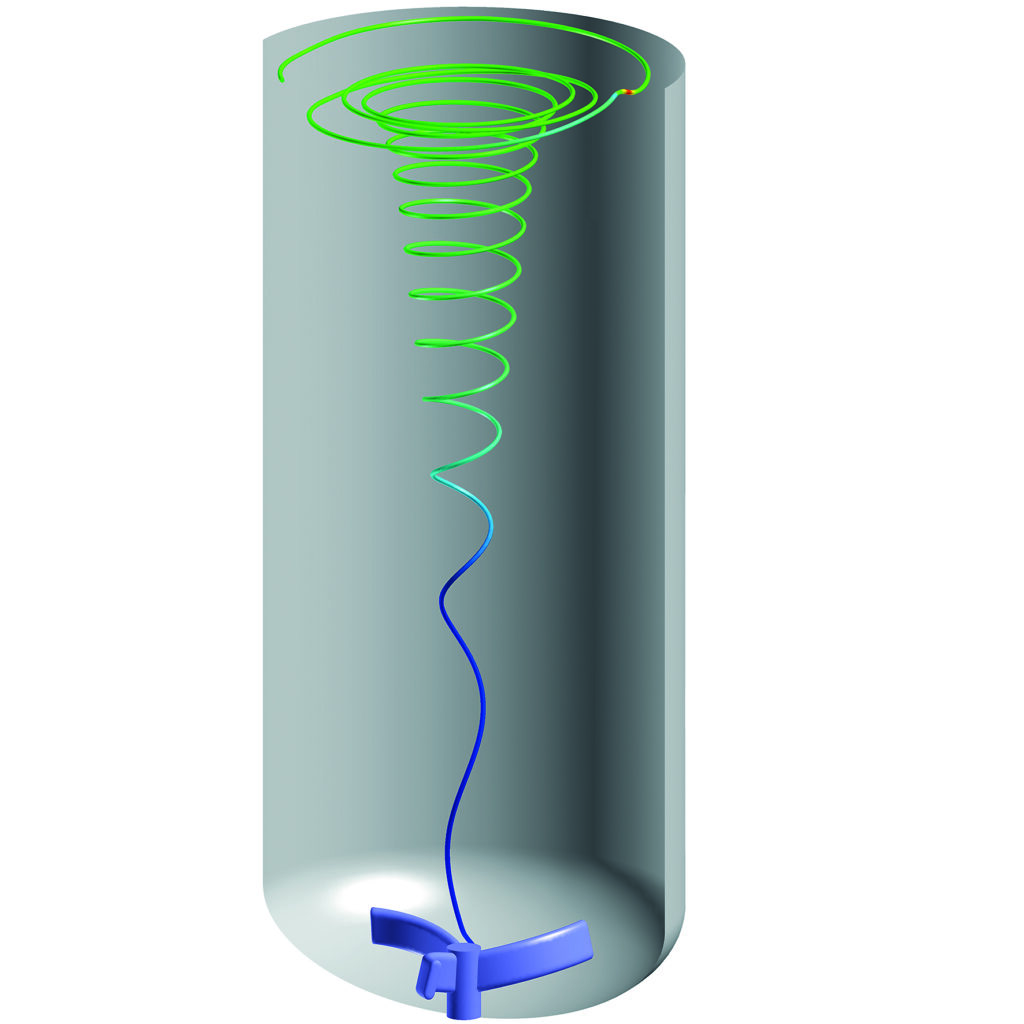

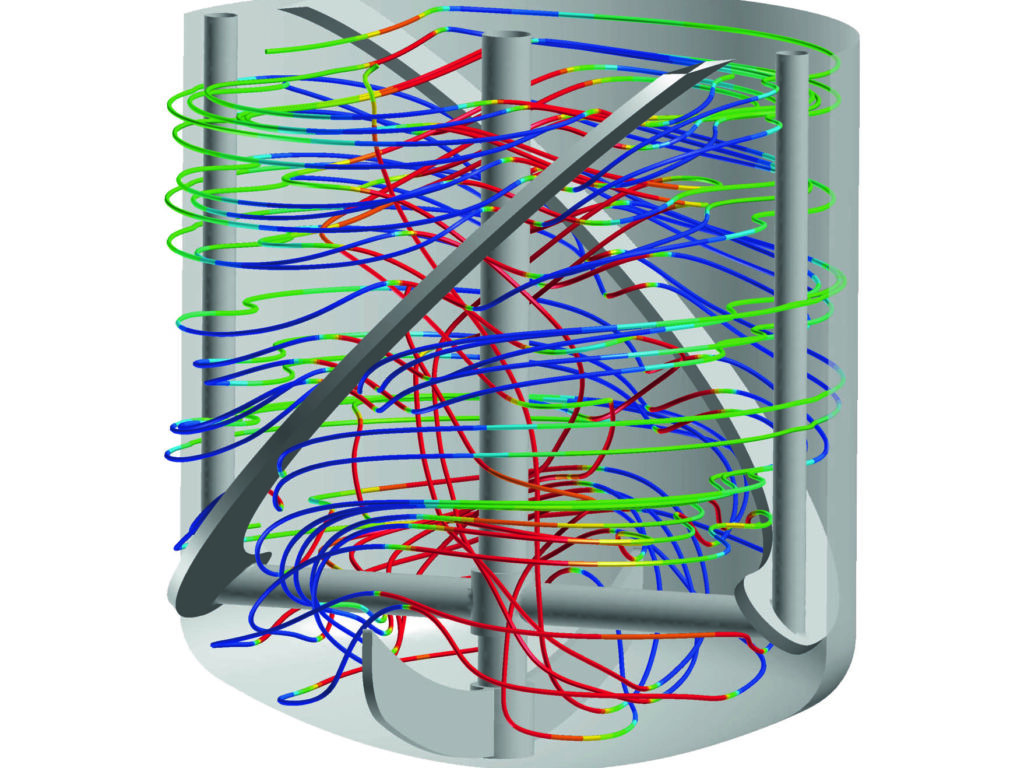

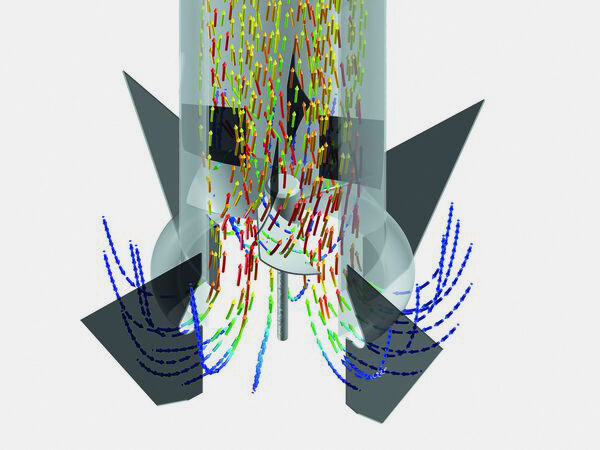

EKATO开发了ISOJET VDT概念,以有效地执行这些任务。由彼此堆叠的多个Isojet级引起的流动力学充当虚拟引流管(VDT),其加速向下的轴向流动。即使在非常薄且高的容器中,这也允许非常短的混合时间。该混合系统的特殊设计可快速平衡任何浓度或温度梯度,从而实现高产品质量。靠近壁的流动模式显示出相应高的向上流动速度,以防止结壳和沉积物。

EPS, PMMA, PVC

一些最常见的聚合物,如聚氯乙烯,膨胀聚苯乙烯和聚甲基丙烯酸甲酯,是用珍珠聚合法合成的。珍珠聚合的特征在于单体在聚合开始时以不溶形式存在。单体液滴分散在水相中并起“小水冷反应器”的作用。

成珠聚合过程中控制产品质量的关键参数是粒度分布,通常还有最终产品的孔隙率。 一般来说,粒度分布较窄的材料对市场更具吸引力。 这个目标意味着对混合系统的苛刻要求:

- 单体在水中的窄液滴尺寸分布

- 小的温度和浓度梯度

- 避免表面上单独的单体相(汇集)

- 聚合物珠粒的均匀悬浮

- 良好的传热

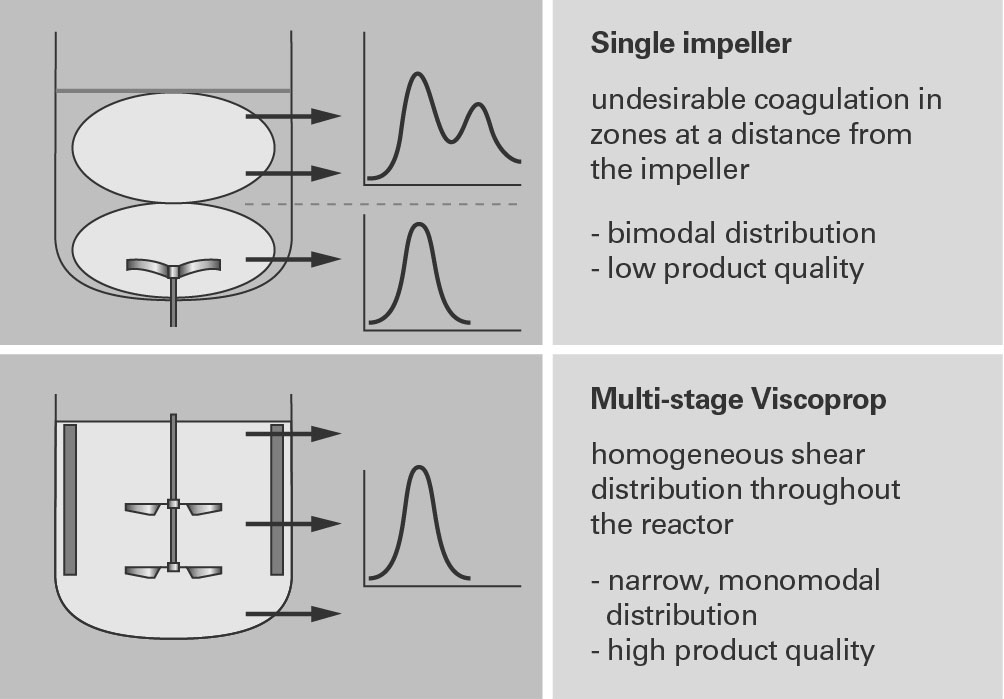

成珠聚合通常使用简单的、通常是单级径向泵送叶轮进行。 然而,特别是在高容器中,它们的混合效率在上部区域受到限制。 下面将讨论 Ekato Viscoprop 搅拌器相对于这些传统混合系统的优势。

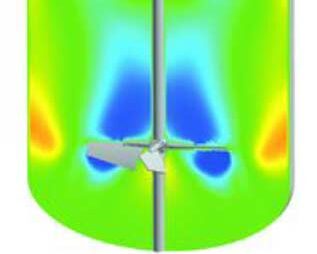

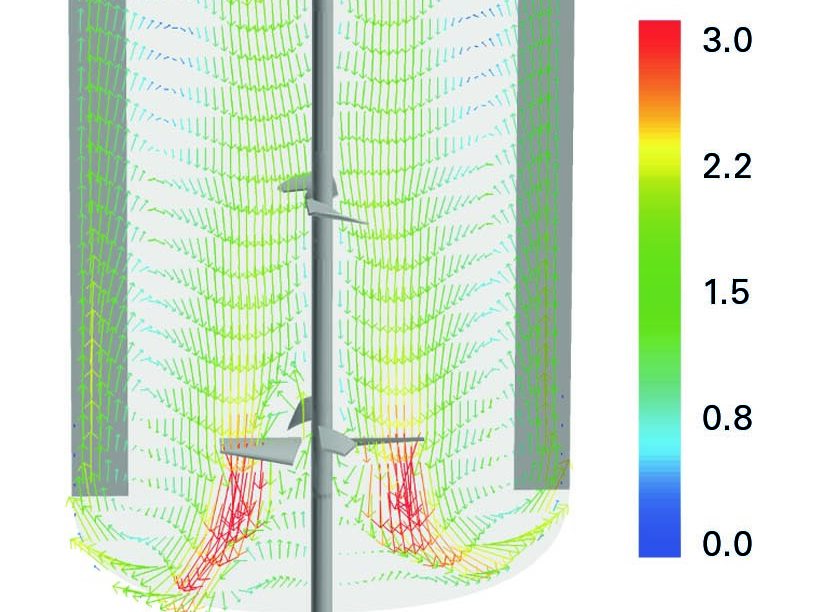

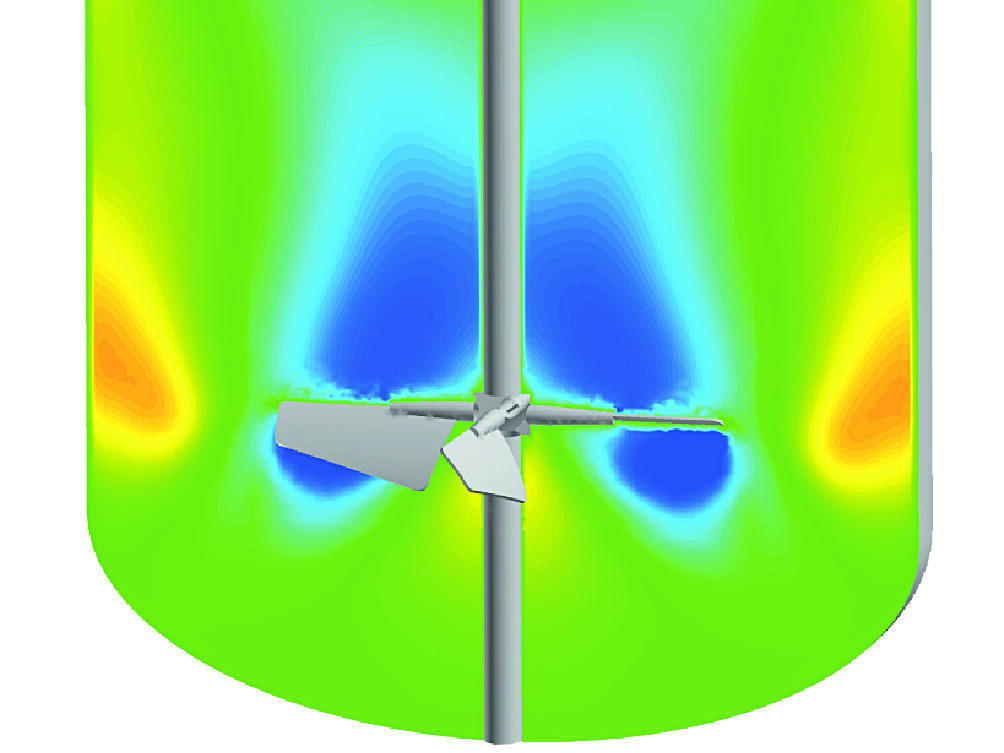

Viscoprop的流速的CFD模拟清楚地表明,搅拌轴附近和叶轮附近的流动是快速的并且沿轴向向下指向。 这通过Viscoprop叶轮的优化形状和将混合系统(包括挡板)定制到反应容器来实现。 靠近反应器壁的是相应的向上流动轮廓,其提供高壁速,这减少了在壁处形成的沉积物。

轴向泵送,多级设置的另一个好处是更窄的粒度分布。

ABS(丙烯腈-丁二烯-苯乙烯共聚物)

ABS的合成通常分两步进行。在第一步中,丁二烯单体经历乳液聚合以制备聚丁二烯分散体(PBL)。然后在第二步中将其与乳液中的苯乙烯 - 丙烯腈(SAN)共聚物反应以达到目标橡胶浓度。在继续用苯乙烯 - 丙烯腈处理之前,重要的是将PBL分散体的粒度调节至所需值。较大的颗粒在最终产品中产生较大的冲击韧性,但表面光泽度较低。 PBL颗粒的最佳尺寸范围是约 0.3-0.5μm。

在搅拌器的剪切场中加载胶乳颗粒随着粒度的增加而增加。如果两个相邻颗粒的乳化剂包膜被不适合的搅拌器系统引入的高局部剪切破坏,它们将凝结成甚至更大的胶乳颗粒。这导致最终产品的机械性能的显着变化。它还导致形成较厚的壁沉积物,其抑制反应产生的热量的消散。因此,必须接受频繁的清洁循环,同时显着降低生产率。 Ekato Isojet B是一种极低剪切叶轮,是PBL反应器的理想选择,特别是作为多级反应器。同时,使用挡板作为额外的热交换器提供非常有效的冷却。