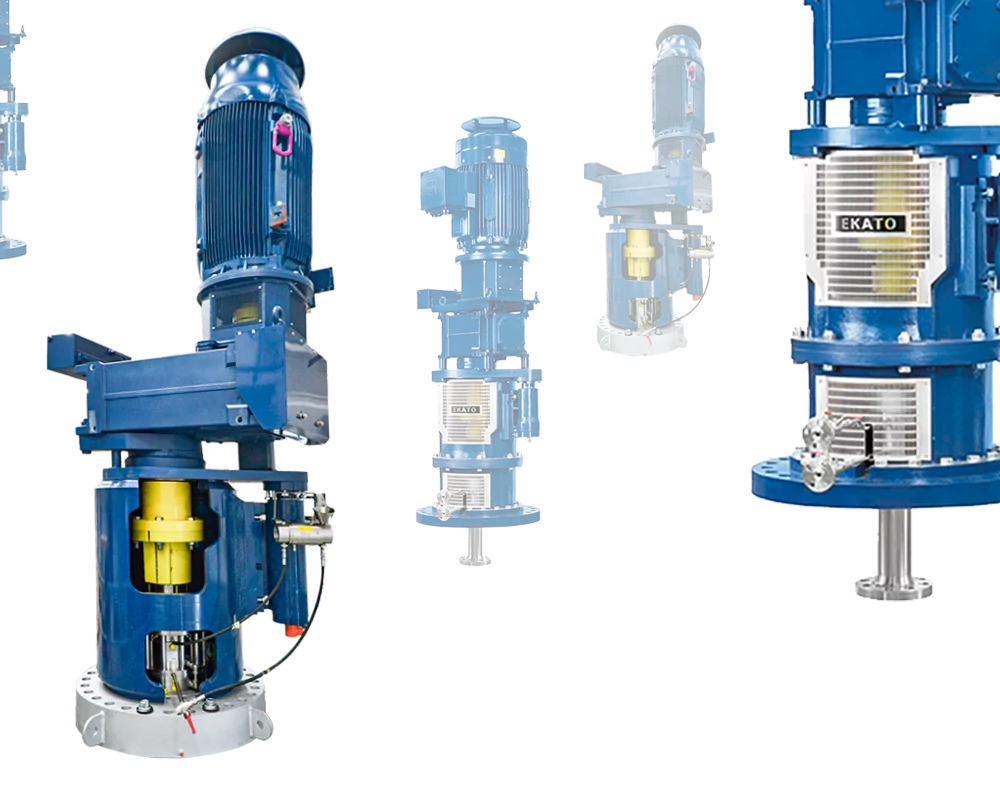

EKATO

传统桨叶(叶轮)

用于轴向、径向和切向流动

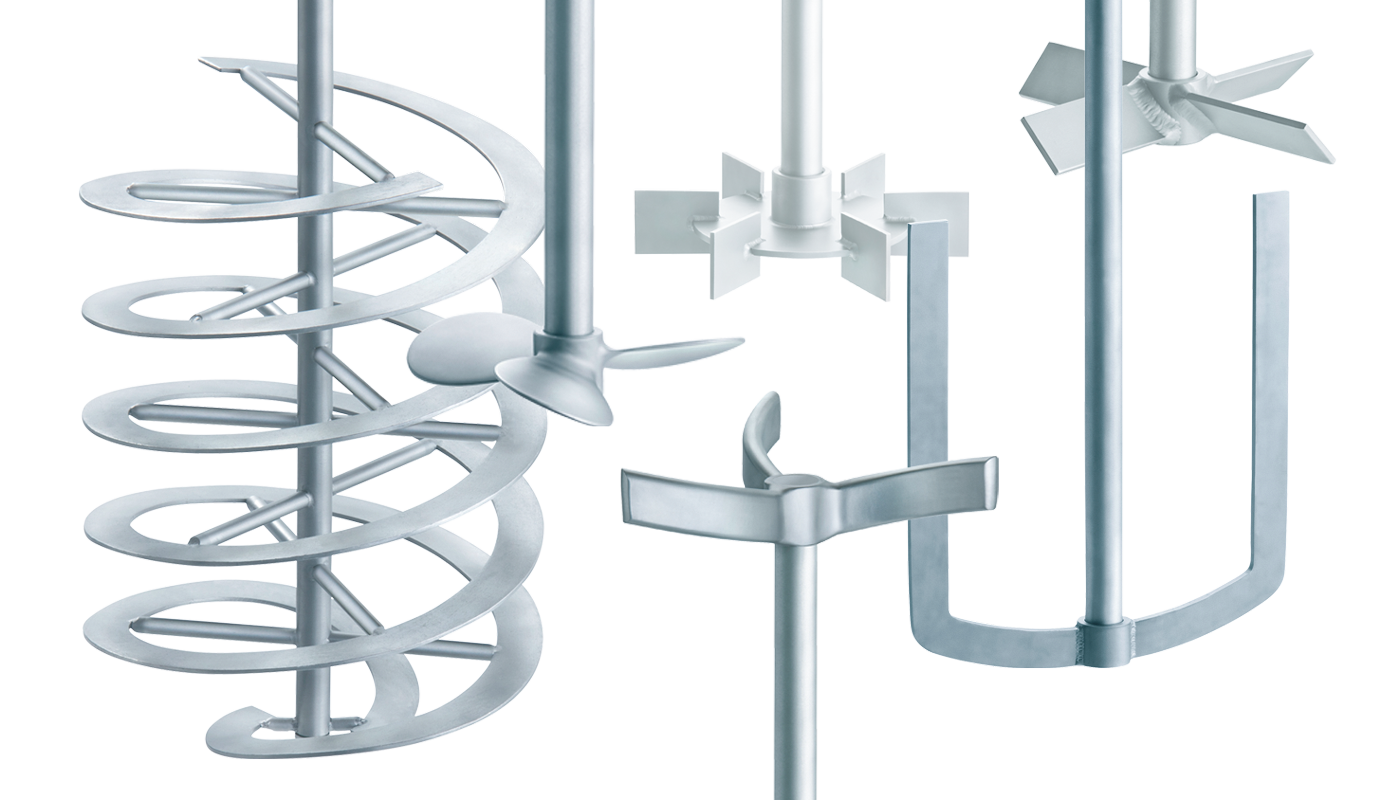

在搅拌混合技术中,各种各样的桨叶(叶轮)被广泛应用。各种各样的设计可以追溯到一些基本类型。这些产品的尺寸和名称符合DIN 28131标准。

目录

原则上,根据以下几个方面对搅拌器进行分类是有用的

- 主要流动方向:轴向、径向或切向

- 桨叶靠近容器壁和中央操作

- 叶尖速度

- 粘度范围或流态:层流、湍流或过渡流

在实际应用中,桨叶通常是按一次流向进行分类的。除了所需的轴向或径向流,每个搅拌器还通过向液体传递旋转运动产生切向流。这样,混合容器内就产生了三维流动。该流场受容器内组件的影响很大。在容器壁上安装折流板通常可以减少搅拌系统中不希望的切向流动。

轴向流桨叶

螺旋桨

用于低粘度介质的典型轴向泵送叶轮是三叶螺旋桨。 这种多功能叶轮特别适用于均质和悬浮。 流型显示出在湍流范围内的强烈轴向吸入和强烈成束的排出流。 出口射流在底部偏转并到达容器壁区域的表面。 液体在螺旋桨区域加速。

折叶开启涡轮桨叶 - Pitch blade turbines

叶片角为 45° 的四叶片变桨叶轮机产生了大致相当的流动模式。 然而,形成了更强的径向分量。 与螺旋桨相对,扩大了应用领域; 可以处理高达 20,000 mPa s 的粘度。 因此应用范围扩展到层流和湍流状态,但由于叶片形状非常简单,效率相对较低。

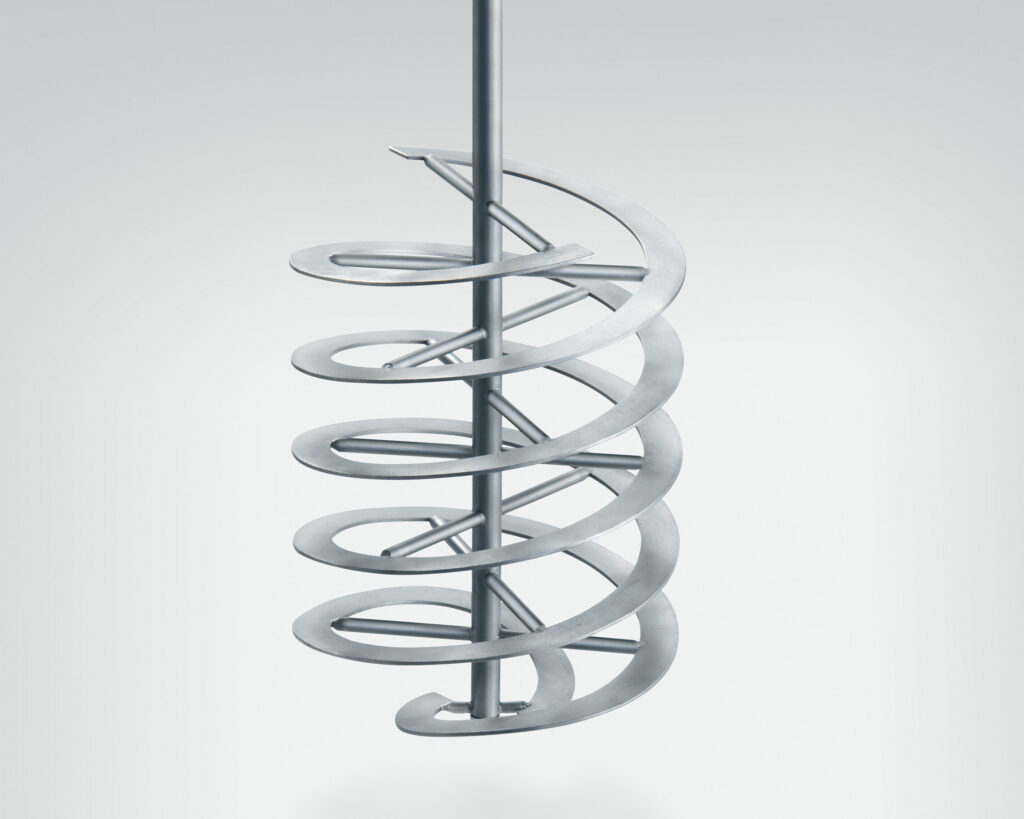

螺旋带桨叶

螺旋带桨叶适用于均质化高粘性介质。 它由一个带状螺旋线组成,该螺旋线通过横杆固定在轴上。 与螺旋桨相反,轴流不是由压差引起的,而是由层流状态中的位移效应引起的。 螺旋带叶轮的一个缺点是必须使用横档来稳定, 这些可以防止安装挡板、汲取管等,这在许多实际应用中可能是有益的或必要的。 直径比为0.9到0.99,螺旋带叶轮是一种接近壁面操作的叶轮。

径向流叶轮

直叶圆盘涡轮桨 - Rushton disc turbine

通常使用的径向泵送叶轮的代表是直叶圆盘涡轮桨。 几个(通常是六个)垂直矩形叶片沿圆周对称布置在水平布置的承载盘上。 平叶片盘式涡轮桨主要用于充气应用。 在这种情况下,这种叶轮的缺点是相对较低的液泛限制以及较高的功率下降。 只有在某些条件下才能扩展到进一步的混合任务。 使用这种叶轮,实际的混合效果主要发生在径向流出的剪切区。

后退曲线桨叶 - Retreat curve impellers

后退曲线叶轮是一种运行速度相对较快的叶轮,(通常)三个叶片沿流动方向向后弯曲。 主要流动方向为径向。 轴向流量取决于叶轮的直径比和底部间隙。 后退曲线叶轮通常与混合系统中的一个或两个指状挡板一起运行,用于均化和改善通常粘度较低的液体的传热。 但是适用性是有限的。 由于后退曲线叶轮的形状最初是为搪玻璃应用设计的,它在流体动力学方面不是最佳的,因此越来越多地被更高效的叶轮所取代。

切线向流动叶轮

锚式桨叶

具有切向流的叶轮的典型代表是锚式桨叶,它通常由平行于轴布置的两个叶片组成。 它们通过沿着容器底部轮廓的横杆连接。 直径比为0.9到0.99的锚式叶轮具有较小的壁间隙。 其主要任务是减少粘附在容器壁上的高粘性边界层的厚度,以加强热交换。 偶尔仍使用的指状或框架叶轮具有类似于锚式叶轮的特性。