生物聚合物

高效混合如何促进循环经济

新市场的出现——生物基聚合物

基于生物质的化学工业基础材料生产工艺的开发具有三个主要目标:

- 使用可再生原材料减少温室气体排放和应对气候变化

- 发展“可持续”循环经济

- 减少化学部门对化石原材料(石油、天然气……)的依赖

尽管生物基产品市场仍处于起步阶段,但由于以下因素,目前正在经历强劲增长:

- 增加消费者对更具可持续性的消费品的兴趣

- 行业和品牌制造商加大力度提供生物基包装材料

- 解决烯烃和一些高需求芳烃的潜在供应短缺问题,鼓励使用新原料和新生产工艺

大规模使用生物基化学面临哪些挑战?

- 与石油基工艺相比的生产成本

- 获得可再生资源

- 公用事业部门的发展

- 生物精炼厂的建设利用不同生物质转化之间的协同作用,例如生物燃料生产和生物产品之间的协同作用

- 开发新的生物基产品

- 市场仍然高度依赖关键的经济和政治因素,例如油价变化,这可能有利于或不利于生物基中间体产能的发展

- 缺乏或相反地引入公共和监管激励措施

生产生物基聚合物的工艺链 - 生物精炼厂

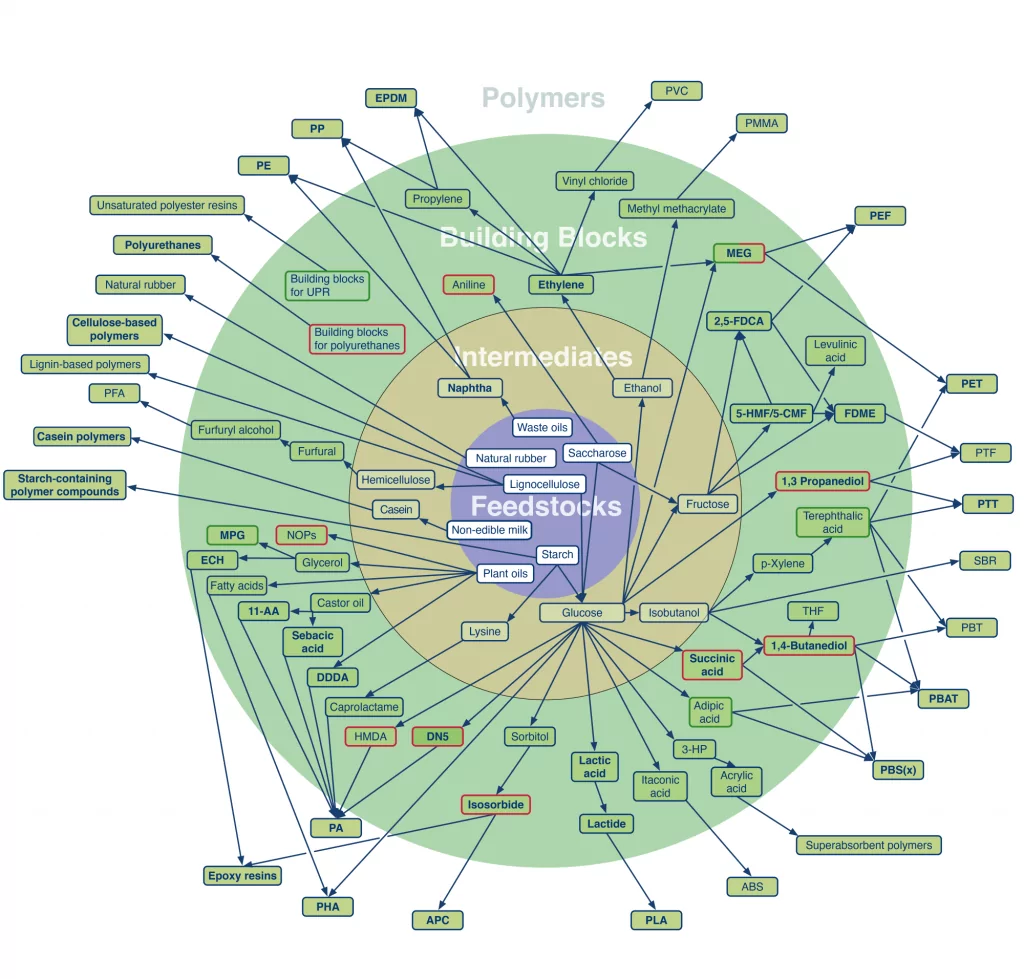

所谓的“生物炼油厂”正在发展成为经典石化工艺的替代品,主要基于石脑油或天然气。 生物精炼厂的原始工艺主要以糖为起始产品,因此与食品和动物饲料的生产竞争。 更现代的工艺,即所谓的第二代生物工艺,旨在利用再生原材料的几乎所有成分,即尽可能多甚至所有植物成分。

几十年来,类似的想法一直是炼油厂的基础,这就是为什么生物炼油厂的基本概念基于已建立的石油化学化学过程。 在生物精炼厂的第一步中,对生物质进行物理材料分离。 然后对主要和副产品进行微生物和/或化学转化反应和热处理。

可以考虑以木质纤维素为基础的生物精炼厂作为示例。 它使用自然干燥的原材料,例如来自造纸工业的稻草、草、森林残余物或含纤维素的废物作为起始产品。 在此基础上,产品在三个不同的生产线中生产:粘合剂、粘合剂、燃料或化学产品可以在木质素生产线中生产。 增稠剂和木糖衍生物,例如尼龙,可以在半纤维素生产线中生产。 在纤维素生产线中,从葡萄糖中获得乙醇或乳酸等发酵产物,可以生产聚乳酸(PLA)。

用于进一步加工成生物聚合物的生物基单体的生产和纯化

好氧发酵在生物基平台化学品或单体的生产中起着重要作用。 搅拌式大型发酵罐是一种高效的工艺解决方案,特别是在传质、传热以及由此可以实现的产量和产品质量方面。 在生产这些生物基单体之后,它们会被纯化,这通常发生在结晶步骤中。 最后进行生物基聚合物的聚合或缩聚。

EKATO 不仅为所有这些不同的工艺步骤提供合适的搅拌器,而且还在各个制造步骤的工艺开发和完整搅拌反应器系统的工程设计中为您提供支持。

一些生物基聚合物产品,如聚乳酸 (PLA) 或其他聚酯已经达到市场成熟度,或者已经处于工艺开发的“主场”。 为了促进对化石原料的依赖——当然,为了实现具有挑战性的气候目标——许多生物基产品及其制造工艺将在未来几年发展到工业规模。 这些工艺的安全放大和各个工艺步骤的能源效率至关重要。

在这些新技术的发展和适应的背景下,EKATO 的现代搅拌和混合技术可以做出重大贡献。