搅拌目的

- Mixing Tasks

优化搅拌技术的关键

混合 / 均匀性

每一个混合过程的目的都是在整个包含体积内达到过程所要求的均匀性。在均质过程中,重要的是要减小由产物添加、传质、化学反应或传热引起的浓度和温度差异。这种混合作用发生在单相和多相系统中。

为了在均质过程中降低能耗或提高生产率,有必要弄清混合时间是否是一个限制因素。对于低粘度液体,混合时间以分钟为顺序,因此往往不是关键的。

对于高粘性介质,情况就不同了。在这里,介质的流变性决定了混合过程。这里需要特殊的,大多数壁挂式搅拌系统,以实现适合过程的搅拌时间。

应该考虑什么?

- 介质的粘度/流变性

- 容器的几何形状

- 搅拌系统的功率输入,特别是工程放大时

固体混合

当混合粉体,特别是散装物料时,确定混合质量起着核心作用。统计原理的知识可以用来获得对实际应用的帮助,这确保了一个有效的程序,以确定混合质量。在这种情况下,将实验室规模的混合时间放大到生产规模也非常重要。

应该考虑什么?

- 晶粒/颗粒尺寸分布和晶体形状

- 水分含量和流动特性

- 避免污染

固液悬浮

悬浮液被理解为物质的非均匀混合物,它由分布在其中的液体和固体组成。悬浮是将这两种物质结合在一起的过程。悬浮搅拌器可用于不同目的的操作。例如,对于固体的溶解,接近底部的固体流化就足够了,而在连续过程中,例如在结晶或矿石浸出中,对悬浮液的均匀性要求最高。

应该考虑什么?

- 工艺要求-完全或均匀地悬浮

- 液体-固体密度差Difference in density fluid - solid

- 固体的颗粒大小Particle size of the solid

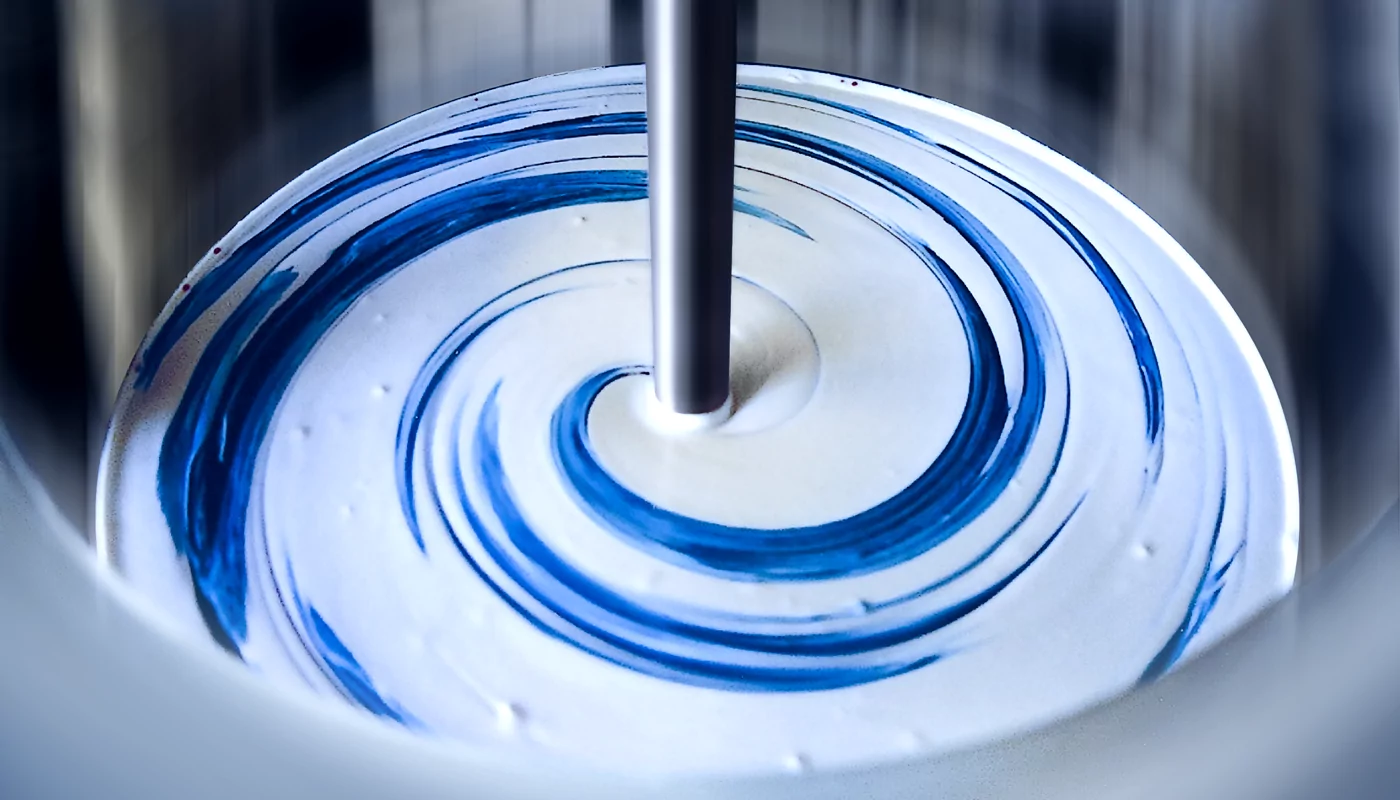

液 – 液分散

液-液分散被理解为两种或两种以上互不相容的液体的混合物。这种混合物被制成并用于许多工业用途。在化学工业中,液体经常相互临时混合,以有针对性地控制萃取或反应。长期稳定的分散剂也产生,例如在制药,化妆品或食品工业。这种长期稳定的液体分散称为乳状液。

应该考虑什么?

- 工艺要求-临时或稳定乳液

- 液相的密度差/界面张力

- 从搅拌系统输入的能量

气 – 液分散

液体的加气在化学、制药工业和生物技术中具有很高的重要性。这里的目的是在分散的气体和液体之间实现最大可能的传质。带有加气系统的搅拌反应器用于化学合成,如氢化或氧化,以及发酵。

应该考虑什么?

- 提高吞吐量和选择性

- 在较低的压力和/或温度下,相同的转化率

- 节省总拥有成本

干燥

干燥是工艺工程中的一个基本过程。湿固体的热干燥是一个传热和传质的结合过程,目的是通过除去水分获得干燥的最终产品。对于潮湿固体在真空下的热干燥,带有混合器的垂直装置是理想的。当设计这些干燥器时,从实验室到生产规模的干燥时间是特别感兴趣的。

应该考虑什么?

- 晶粒/颗粒尺寸分布和晶体形状

- 水分含量和流动行为

- 避免污染

传热

在许多搅拌过程中,传热是搅拌元件与锅炉几何结构以及冷却和加热元件必须满足的基本要求之一。典型的任务是:在放热或吸热反应中保持产品温度恒定,或通过在预定时间内加热或冷却来设定一定的产品温度。

应该考虑什么?

- 被加热或冷却介质的粘度/流变性

- 稳态或非稳态过程

- 可用的交换区域,特别是工程放大