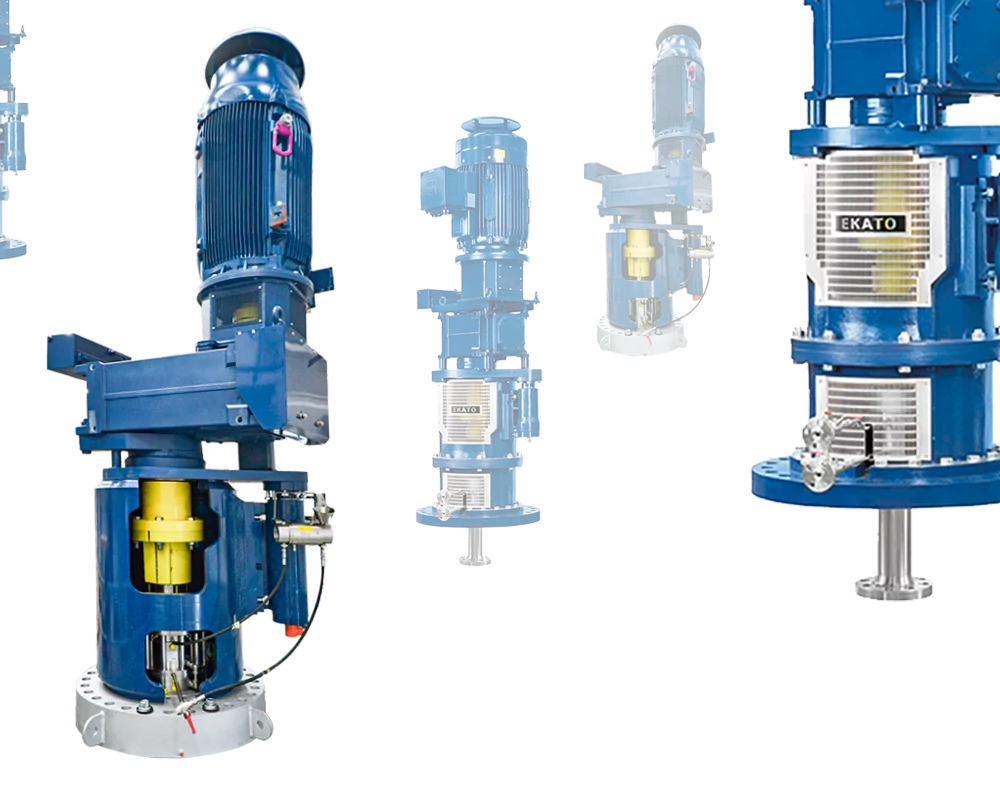

EKATO

双端面机械密封

满足零泄漏和挑战性要求的机械密封

双端面液体润滑机械密封是搅拌混合应用中最常见的类型。 这些密封件几乎可以在混合容器中的所有操作条件下使用。 它们也可以设计为气体润滑型,在这种情况下,向密封腔连续供应气体可保持边际间隙,从而防止密封环磨损。

目录

用于低压范围的液体润滑机械密封 ESD34N

功能和应用

- 双端面液体润滑机械密封,适用于高达 7 bar (abs.)

- 背对背布置的两对相同的密封环

- 可提供带有用于冷却的短的热收集器

- 可提供储存容器上配备水夹套以进行冷却

优点

- 模块化设计, 标准化的易损件

- 双端面, 即使在低压范围内

- 尺寸紧凑,适用于狭小安装空间

- 填料密封的理想替代品

- 为节省成本而设计

工作极限

- 操作压力: 真空...7 bar (abs.)

- 容器温度: -50...+400°C

- 轴径: 40...220 mm

- 滑动速度: 0...5 m/s

EKATO ESD34N 最适用于

- 大宗化学品

- 聚合物

- 药品和化妆品

- 特殊化工品

- 配制消费品

- 生物燃料和生物精炼产品

- 储罐

双端面液体润滑机械密封 ESD34G

功能和应用

- 液体润滑双端面机械密封

- 背对背布置的两对相同的密封环

- 适用于中压范围高达 40 bar (abs.) 的理想的机械密封

- 模块化设计的使用开辟了许多不同的扩展选项

- 世界范围内最常用于搅拌器的机械密封

- 可提供带有用于冷却的短隔热

- 可提供带冷却水夹套的产品

优点

- 极其坚固的结构可节省生命周期成本

- FEA 确保在每个密封环中优化应力分布

- 特殊的弹簧设计即使在搅拌机轴发生显着位移的情况下也能确保均匀的预应力条件

- 在极其恶劣的条件下几乎为零泄漏

工作极限

- 操作压力: 真空...40 bar (abs.)

- 容器温度: -50...+400°C

- 轴径: 40...220 mm

- 滑动速度: 0...5 m/s

EKATO ESD34G 适用于

- 大宗化工品

- 聚合物

- 特殊化工品

- 配方消费产品

- 药品和化妆品

- 生物燃料和生物精炼产品

- 湿法冶金

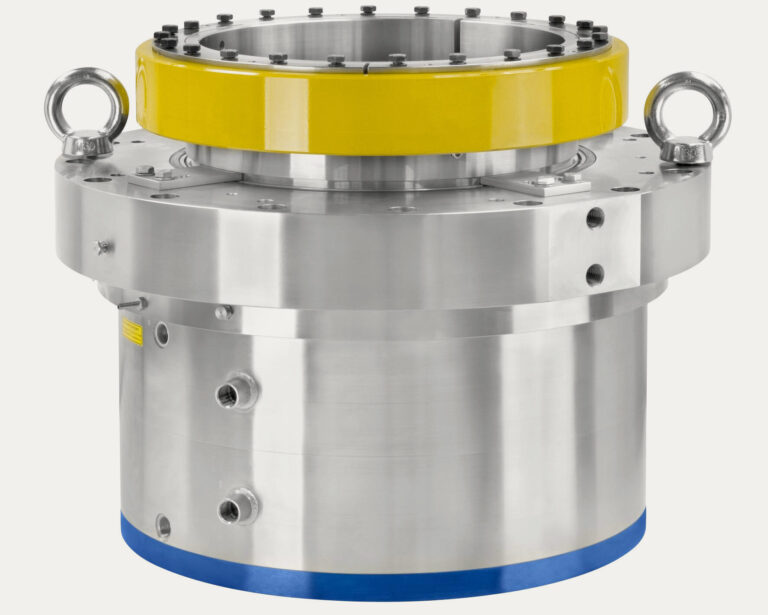

高压机械密封 ESD64H

功能和应用

- 用于高压应用的液体润滑双端面机械密封

- 坚固的高压密封,四个几何形状相同的密封环背对背布置

- 即使压力反向,密封环的位置也保持不变

- 在包括供给系统在内的高压工艺中的应用 - 对可靠性的高要求

- 适用于压力的频繁变化、极高的温度和显着的搅拌轴位移

优点

- 耐压力变化

- 抗搅拌轴位移

- 机械密封受压不变形

- 可能的高温/更好的散热

- 最小泄漏

- 延长使用寿命

工作极限

- 操作压力: 真空...100 bar (abs.)

- 容器温度: -50...+400°C

- 轴径: 40...220 mm

- 滑动速度: 0...3 m/s

EKATO ESD64H 适用于

- 大宗化工品

- 特殊化工品

- 湿法冶金

液体润滑机械密封 ESD64G

功能和应用

- 双端面液体润滑机械密封

- 四个几何形状相同的安装式机械密封环

- 理想的机械密封,适用于高达 40 bar (abs.) 的中压范围内的大直径

- 可提供用于冷却的短热阱

- 可选配水夹套

优点

- 对压力变化有很强的抵抗力

- 抗轴挠度强

- 机械密封受压不变形

- 散热好

- 最小的泄漏

工作极限

- 容器压力: 真空...40 bar (abs.)

- 容器温度: -50...400°C

- 轴径: 240...500 mm

- 滑动速度: 0...5m/s

EKATO ESD64G 适用于

- 大宗化工品

- 聚合物

- 特殊化工品

- 无菌工艺

- 湿法冶金

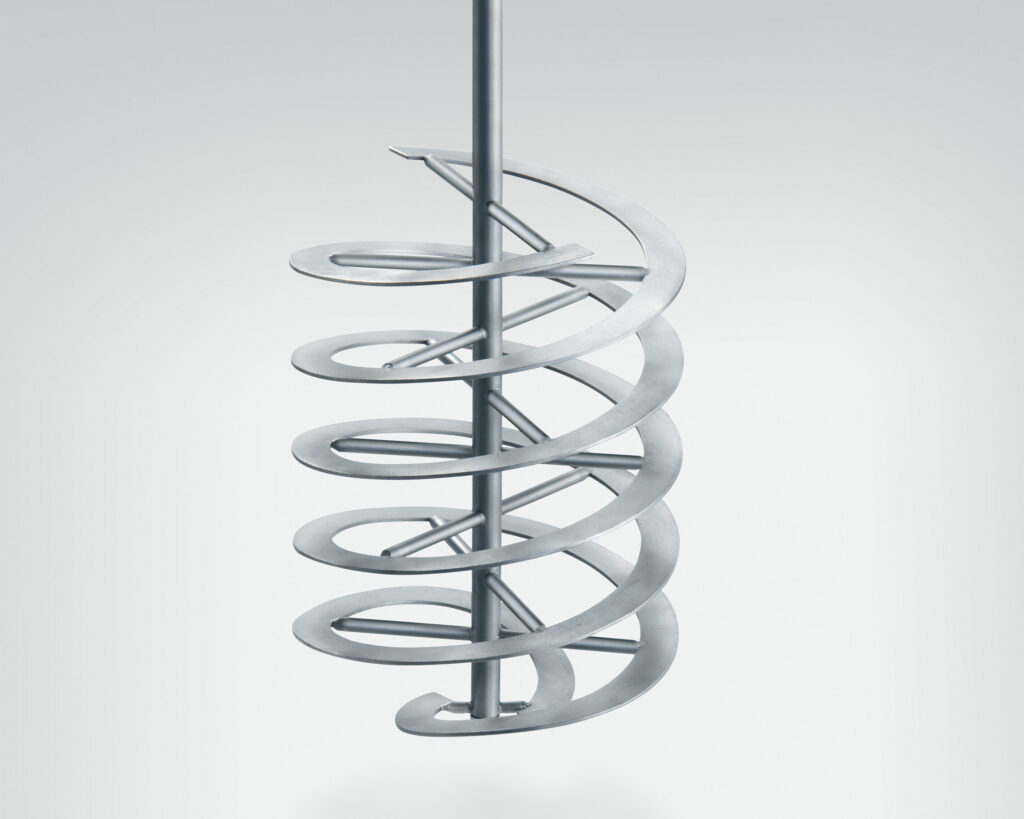

产品物料润滑机械密封 ESD44

功能和应用

- 用于浆液应用的双端面液体润滑机械密封

- 一对产品侧密封环延伸到容器空间

- 表面光滑,设计最大限度地减少间隙以防止角落积料 - 可以彻底清洁

- 密封研磨悬浮液和粘性或硬皮介质(低于液位,侧入式安装)

- 也可提供无菌密封结构 (ESD44S) - 任何方向均可

优点

- 无死角,可彻底清洁

- 可以消毒

- 坚固的设计

工作极限

- 操作压力: 真空...16 bar (abs.)

- 容器温度: -50...+230 °C

- 轴径: 40...300 mm

- 滑动速度: 0...5 m/s

EKATO ESD 44 适用于

- 特殊化工品

- 配方消费产品

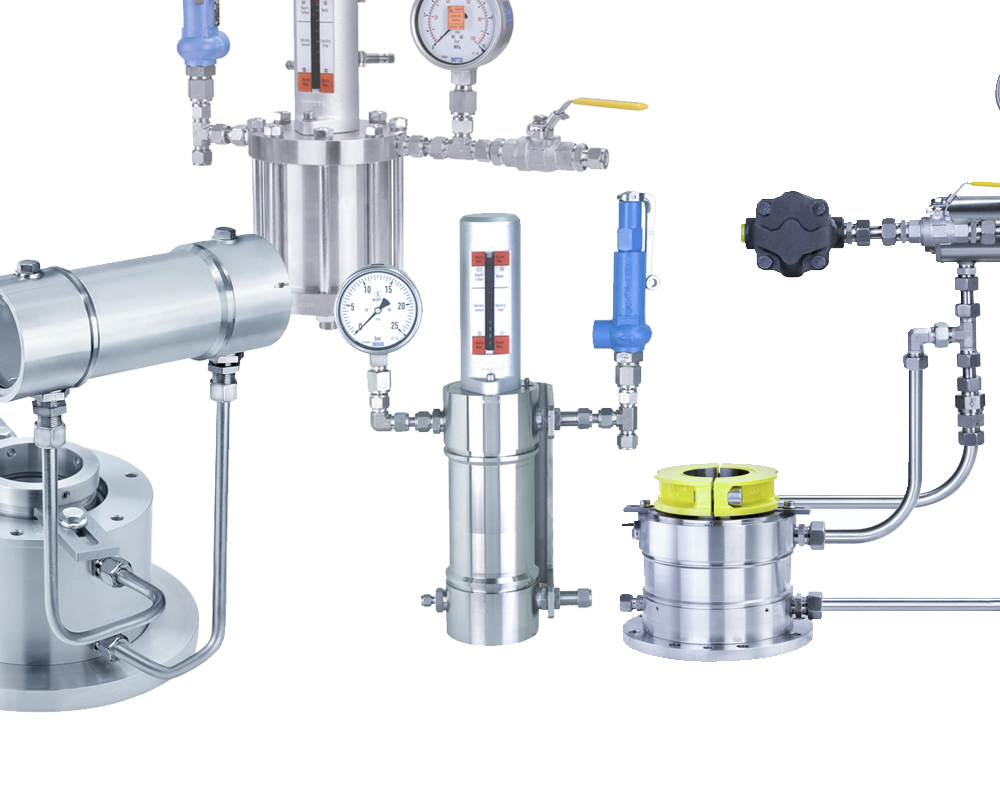

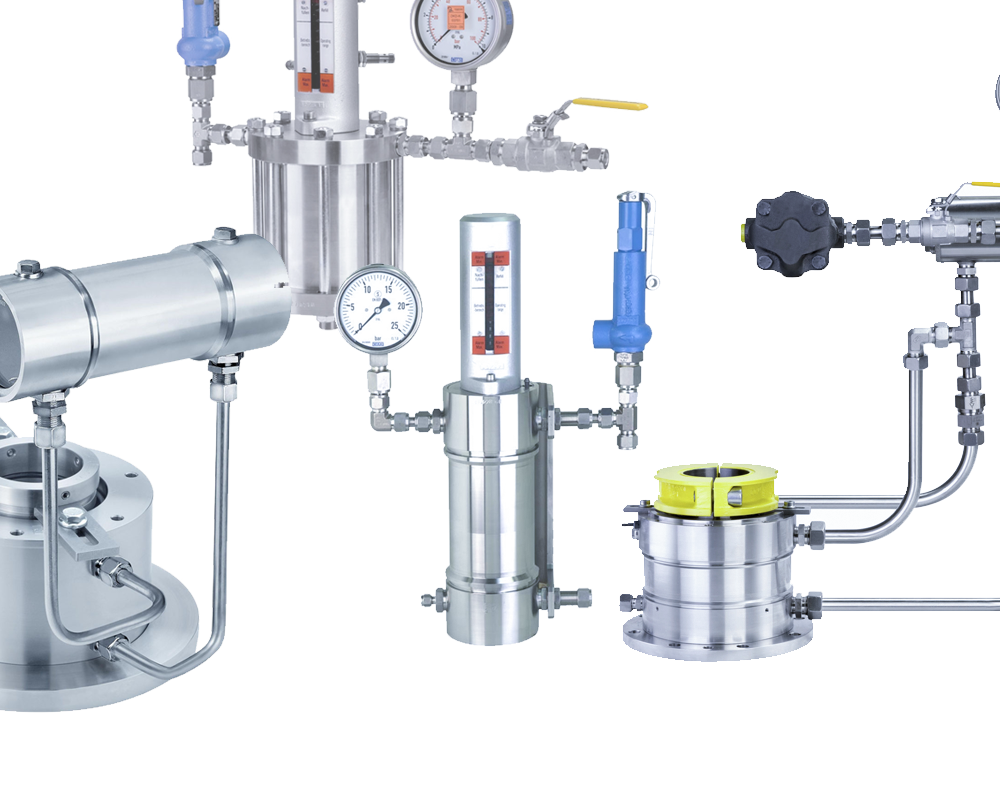

无菌密封 ESD34/44S

功能和应用

- 无菌工艺的理想选择

- 提供完整的无菌系统,包括无菌安装

- 由板式换热器冷却的密封液体

- 用新鲜蒸汽对冷凝水进行连续灭菌

优点

- 来自单一来源的完整无菌系统、机械密封和无菌安装

- 即装即用的整装单元

- 无间隙: 无菌工艺的理想选择

- ESD 无菌装置几乎无需维护,能耗极低

工作极限

- 操作压力: 真空....4.5 bar (abs.)

- 蒸汽温度:130°...150°C

- 轴径: 40...300 mm

- 滑动速度: 0...5 m/s

EKATO ESD ESD34/44S 适用于

- 特殊化学品

- 药品和化妆品

- 生物燃料和生物精炼产品

高速机械密封 ESD114

功能和应用

- 液体润滑双端面机械密封

- 用于高固体含量和无菌工艺的产品

- 非常适合高速轴

优点

- 易于清洁和消毒

- 延长使用寿命,即使在高速机器上

工作极限

- 操作压力:真空...6 bar (abs.)

- 容器温度: -20...+200°C

- 轴径: 40...220 mm

- 滑动速度: 0...20 m/s

EKATO ESD ESD114 适用于

- 配方消费产品

- 药品和化妆品

下载

以下资料可供下载

- Mechanical Seals Overview (EN)

- Mechanical Seal ESD34N (EN)

- Mechanical Seal ESD34/44S (EN)

- Mechanical Seal ESD34G (EN)

- Mechanical Seal ESD34G (EN-CN)

- Mechanical Seal ESD44 (EN)

- Mechanical Seal ESD64H (EN)

- Mechanical Seal ESD64H (EN-CN)

- Mechanical Seal ESD114 (EN)

- Mechanical Seal ESD114 New Generation (EN)