EKATO Worldwide

EKATO Always Near You

EKATO Australia

Optimized Mixing Technology for the Oceania Market

EKATO Australia has been established since 1998. Based in Perth, Western Australia, EKATO Australia provides a full range of sales and technical service support to our customers in the Oceania region. Our qualified and motivated team from EKATO Australia is responsible for the distribution and service of products and spare parts from all three divisions of the EKATO GROUP – EKATO RMT, EKATO FLUID and EKATO SYSTEMS.

The aftermarket activities of EKATO Australia cover the entire equipment life-cycle including assembly, commissioning new installations as well as spare parts service. EKATO Australia also provides a specialist mechanical seal repair workshop facility for all EKATO products.

Service Center Australia

We offer our customers maintenance and overhaul as well as preventive maintenance of the mechanical seals in our workshop with state of the art equipment:

- Assessment

- Diagnostic

- Disassembly

- Cleaning

- Repair

- Static pressure test and dynamic test on the special test rig with specified operating pressure and shaft speed for most types of EKATO mechanical seals

The benefits for our customers:

- Quick local maintenance service

- High qualified and experienced staff

- All data relating to measurements and mechanical seal condition are carefully recorded and documented during every maintenance / repair cycle for systematic analysis as a reliable basis for developing suitable PM measures

- 6 month warranty certificate for repaired mechanical seals

- Increased mechanical seal availability and reliability

- Improved cost - benefit ratio

EKATO Chile

Optimized Mixing Technology for the South American Market

EKATO 中国

优化的搅拌技术,用于中国市场

EKATO is present in P.R. China with an own commercial subsidiary since 2003. With the establishment of the production company “EKATO (Shanghai) Agitation Equipment Co., Ltd” in 2016, a new step has been achieved.

In July 2018, EKATO China celebrated the opening of their new premises in Shanghai. The new facilities are now located in the south-west of Shanghai, offering about 2,700 sq.m. space in total

New location

In July 2018, EKATO China celebrated the opening of their new premises in Shanghai. The new facilities are now located in the south-west of Shanghai, offering about 2,700 sq.m. space in total.

Learn moreWorkshop Capabilities at EKATO China

The 2,100 sq.m. workshop offers the possibility for:

- Local manufacturing of agitators parts

- Welding of impellers

- Agitator assembly and inspection

- Stock for smaller wear parts

- Repair of mechanical seals and other agitator parts

- Trials in own laboratory

Laboratory

A state of the art laboratory equipped with LM6, SRT50 and VPT50 pilot plants is available, in order to perform in-house trials for cosmetic and pharmaceutical customers.

Mechanical Seal Testing and Repair

The assembled mechanical seals can be tested dynamically in the test pit with pressure and temperature. Furthermore, a lapping machine is available, to ensure that mechanical seals can be repaired directly at EKATO CHINA in Shanghai.

EKATO India

Optimized Mixing Technology for the Indian Market

EKATO India has a full-fledged service set-up with an experienced team of service engineers trained at EKATO Germany to provide assistance for:

- Erection / start-up / commissioning

- Repair / maintenance / trouble shooting

- Modifications and training

Our prestigious supply references for most demanding and critical applications include BCPL, EIL, HMEL, IOCL, MRPL, GAIL, RIL, UCIL and many more.

Repair of Meachanical Seals at EKATO India

EKATO India has a complete setup for carrying out repair and reconditioning of mechanical seals efficiently in a short time. A fully automated test rig ensures test run of mechanical seals at different operating pressures and rpm.

- Services rendered: cleaning, lapping and repairing, testing, certifying for usage

- Serviced type of seals: single-acting, double-acting and triple-acting

Benefits to the customer

- Quick servicing of seals locally

- Reduced downtime in case of breakdown or plant shut down

- All seals dynamically tested in operating pressure and speed

- 6 month warranty certificate for all re-conditioned seals

Mechanical seal dynamic test rig specifications

- Dynamic test rig for seals up to shaft diameter 200 mm

- Max. speed - 300 rpm

- Max. pressure - 70 bar

Laboratory

EKATO India offers EKATO SYSTEMS vacuum processing units for trials that are ideally suited for a wide range of applications such as mixing and homogenizing of liquids or high viscous materials as well as for mixing and drying of solids.

UNIMIX

- State-of-the-art vacuum processing technology for low to high viscous media (mixing, homogenizing, tempering, degassing, etc.)

- Applications: creams, mascaras, toothpastes, lotions, ointments, emulsions, etc.

- Units from 2 litres up to 50 litres processing capacity

SOLIDMIX

- Vertical vacuum processing and bulk solids mixer and dryer

- Handles free flowing solids and pasty products

- Applications: API, fine chemicals and chemical products, etc.

- Units from 20 litres up to 100 litres processing capacity

Download

The following material is available for download.

EKATO Japan

Optimized Mixing Technology for the Japanese Market

Your Partner in Japan since 1994! Each of customer challenge is very different. Our company is specialized in solving customer’s problems and provides solutions using state-of-the-art mixing technology.

We will hear the problems that our customers currently have, offer optimal impellers and mixing environment selection as well as free estimates. Required information is only general information such as tank dimensions and content density. For special mixing requirements, please contact us.

Information on Testing in Japan

EKATO JAPAN offers EKATO SYSTEMS vacuum processing units for trials that are ideally suited for a wide range of applications such as mixing and homogenizing of liquids or high viscous materials.

The laboratory equipment is available on a rental basis, thus enabling to perform tests in customer’s environment. Following laboratory machines are available in Japan for testing purposes – please do not hesitate to contact us.

Laboratory Mixer UNIMIX LM3

"UNIMIX LM3" can easily collect important data such as "temperature" "pressure" "speed" in product development. A homogenizer attached to the bottom of the tank enables internal circulation to return the product directly to the tank without sending the product to the outside, and can also be used for product discharge and cip.

Learn moreLaboratory Mixer UNIMIX SRT 50

Like the LM 3, the UNIMIX SRT 50 is equipped with a high-performance homogenizer. The main impeller EKATO PARAVISC enables efficient mixing and uniform temperature distribution. The laboratory equipment is available on a rental basis, thus enabling to perform tests in customer's environment.

Learn moreEKATO Netherlands

Optimized Mixing Technology for the Dutch Market

Our team consists of

Sandra Heiwegen

- Responsible for all spare parts and service related business.

- E-Mail: sandra.heiwegen@ekato.com

Aart van der Vliet

- Responsible for sales in Flemish Belgium and the southern part of the Netherlands.

- E-Mail: aart.vandervliet@ekato.com

Peter Haesen

- Responsible for sales in the Netherlands (except south-Limburg and Zeeuws Vlaanderen).

- E-Mail: peter.haesen@ekato.com

- Tel.: +31 33 2460404

EKATO Russia

Optimized Mixing Technology for the Russian Market

Service Center Russia

We offer our customers maintenance and overhaul as well as preventive maintenance of the mechanical seals in our workshop with the state of the art equipment

- Assessment

- Diagnostic

- Disassembly

- Cleaning

- Repair

- Static pressure test and dynamic test on the special test rig with specified operating pressure and shaft speed for most type of EKATO mechanical seals

The benefits for our customers

- Quick local maintenance service

- High qualified and experienced staff

- All data relating measurements and mechanical seal condition are carefully recorded and documented during every maintenance / repair cycle for systematic analysis as a reliable basis for developing suitable measures

- 6 month warranty certificate for repaired mechanical seals

- Increased mechanical seal availability and reliability

- Improved cost - benefit ratio

EKATO Singapore

Your Connection to the EKATO Group in Singapore

Service Center Singapore

We offer our customers professional supervision service for site service, mechanical seals refurbishment & OEM repairs in our workshop.

Key services

- Installation, assembly and commission supervision for EKATO agitators & components

- Consultation of preventive maintenance schedules, supervision & implementation by our specialized EKATO service staff

- Customized training programs

- Trouble-shoot operating issues, inspection & condition assessment

- Support plant shutdown maintenance & repairs activities

- Manufacturer warranties

Customer benefits

- Fast & prompt support

- Customer orientated

- Competent technical support

- Expert supervision service

- Highly qualified & experienced service personnel

- Quick turnaround repairs

- Uncompromised quality assurance

- Increased agitator reliability & reduced downtime

EKATO South Africa

Your Connection to the EKATO Group in Africa

EKATO Africa (Pty) Ltd was established in 2007 and is based in Johannesburg, South Africa. The company takes care of over 46 countries across the African continent, with installations in Namibia, South Africa, Democratic Republic of Congo, Mauritius, Madagascar, Botswana, Mauritania, Tanzania, Nigeria, Ghana, Cameroon, Burkina Faso, Mali, Mozambique and Kenya. We represent a complete diverse market, covering all divisions of the EKATO GROUP: EKATO RMT, EKATO FLUID and EKATO SYSTEMS.

We have a network of agency agreements in most industrialized African countries, ensuring that we are within an arm’s length to our clients and offering the right equipment for each application.

EKATO Africa (Pty) Ltd is proud of its state-of-the-art service center, where we are able to repair mechanical seals with shaft diameters of up to 400mm. With our own seal face lapping machine, we are able to give our customers the quickest turnaround time and also maintain the highest world standards, ensuring we offer our clients the best value.

Service Center South Africa

We offer our customers maintenance and overhaul as well as preventive maintenance of the mechanical seals in our workshop with state-of-the-art equipment

- Installation

- Commissioning

- Critical spares

- 24/7 service personnel call out

- Diagnostic

- Disassembly

- Cleaning

- Repair

- Mechanical seal exchange service

- Static pressure test and dynamic test on the special test rig with specified operating pressure and shaft speed for most types of EKATO mechanical seals

Customer benefits

- Fast & prompt support

- Customer orientated

- Competent technical support

- Expert supervision service

- Highly qualified & experienced service personnel

- Quick turnaround repairs

- Uncompromised quality assurance

- ncreased agitator reliability & reduced downtime

EKATO Africa Test Pit

At EKATO Africa, we also can offer test runs for smaller agitator sizes to our customers

- 75m² tank volume

- 37 kW VSD testing power

EKATO USA

Your North American Connection to the EKATO Group

Based on a vast network of sales and service centers thoughout North America, EKATO Corporation can guarantee exceptional customer service for the highest degree of plant availability and operational reliability of EKATO equipment.

EKATO Corporation offers state-of-the-art solutions with German engineering, available in the USA with possible deliveries of complete agitators within 4 weeks.

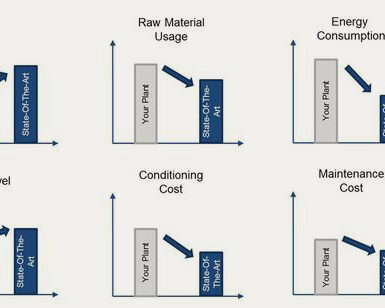

Process & Reactor Improvement

Do you know what's possible?

- Shortened blend and batch times

- Improved safety

- Improved quality and consistency

- Process guarantee

- Reduced operational expense

With EKATO’s 85+ years of knowledge about reactors and their related upstream and downstream processes, combined with the use of our state-of-the-art mixing technology, we partner with our clients to develop the best-in-class chemical processes worldwide.

A typical EKATO process & reactor improvement project has five stages:

- Process Assessment: Onsite analysis of your existing process. Develop Project Goals: Yield, product quality, safety, reliability, raw material and energy savings, lean process etc. Roadmap of the Process: EKATO will produce a report as a result of the assessment which will define the agreed expectations and be the roadmap for the path forward

- Lab and Pilot Testing: test all possible process changes in the lab including process risk analysis

- Scale up: CFD + FEA, etc…

- Feasibility and Budgeting Report: Support the management decisions with clear descriptions and calculations

- Project Management: Basic design, Detail design, Hardware purchasing, manufacturing, Documentation, Quality assurance, Assembly / installation, Start up and operation assessment and continuous improvement

US Rapid Response Mixing Technology

EKATO’s US Rapid Response Program (RRP) is custom designed, state-of-the-art mixing technology available on short notice. Typical delivery times from time of purchase would be 4 weeks and even sooner on request. This is achieved by having designs, proposals and assembly done directly out of our assembly facility in Oakland NJ.

The agitators of EKATO’s EM and FD series will be designed for your specific process requirements, serving a wide range of applications.

- Industrial Agitators EKATO-EM (RRP)

- Compact Agitators EKATO-FD (RRP)/KD/HWL-A

Our Local Lab Capabilities

Lab Capabilites

- Mixing and drying demonstrations

- Feasibility trials

- Process development

- Scale-up

- Process optimization

- Technology seminars

- On-site training classes

- Rental equipment

Products

- Liquids

- Semisolids and Pastes

- Solids

Equipment List

UNIMIX Vacuum Process Systems

- Lab scale units starting at 1 Liter (0.26 Gallons) usable volume.*

- Pilot scale units up to 50 Liters (13 Gallons) usable volume.*

- Commercial scale units up to 1,000 Liters (264 Gallons) usable volume.**

- Commercial scale units up to 10,000 Liters (2,638 Gallons) usable volume.***