EKATO

Hydrogenation Plants for APIs & Pharma Manufacturing

Hydrogenation Technology in API Production

The pharmaceutical industry demands flexible, cleanable, and modular solutions for production. Hydrogenation is a key step, enabling critical chemical transformations that impact drug quality and safety. With over 90 years of expertise, EKATO delivers custom-engineered hydrogenation plants tailored to pharmaceutical needs. Our solutions combine advanced mixing, precise control, and full GMP compliance—ensuring purity, consistency, and process safety. From lab to commercial scale, EKATO optimizes API manufacturing with scalable, regulatory-compliant hydrogenation technology.

Critical Parameters in API Hydrogenation

Successful API hydrogenation depends on precise control of multiple process parameters that significantly impact reaction outcomes:

- High Pressure: Typically ranging from 2-16 bar, pressure management directly affects reaction kinetics, selectivity, and operational + environmental safety considerations.

- Catalyst Type and Loading: Selection between heterogeneous (Pd/C, Pt/C, Nickel) catalysts based on reaction specificity requirements.

- Temperature Control: Precise temperature management (usually between 20-150°C) influences reaction rates and product selectivity while preventing potential side reactions.

- Mixing Efficiency: Critical for gas-liquid mass transfer, uniform catalyst distribution, and heat transfer.

- Cleanability & GMP Compliance: Process plants that are easy to clean

Free On-Demand Webinar

Are you ready to dive into the technical world of API hydrogenation?

Discover the essentials of agitated hydrogenation processes, explore innovative design concepts for agitated hydrogenation reactors, and learn about cutting-edge modular hydrogenation plant technology – all centered around API production.

Julian Urich

Project Manager Sales

EKATO Rühr- und Mischtechnik GmbH

+49 7622 29 610

julian.urich@ekato.com

Project Manager Sales

EKATO Rühr- und Mischtechnik GmbH

+49 7622 29 610

julian.urich@ekato.com

.

Process Consultation

Contact us today to connect directly with our Sales Project Manager and discover how we can enhance your process, equipment, and overall plant efficiency.

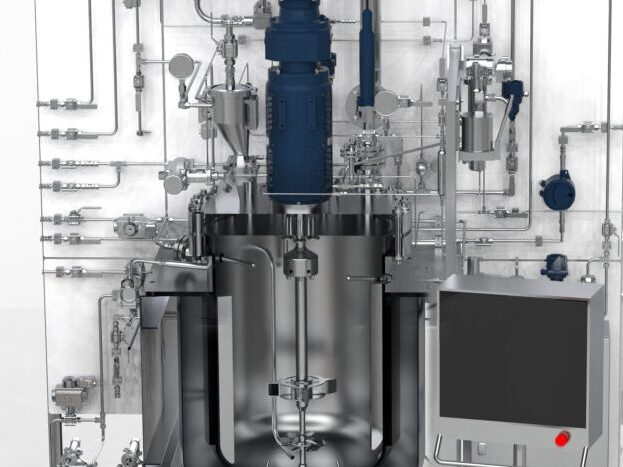

Small-Scale Hydrogenation Unit for Pharmaceuticals

Hydrogenation Reactor

Design Data

Temperature: -25 to 150 °C

Pressure: FV / 16 bar

Filling Volume: 20 to 500 L useful volume

Material Reactor: Stainless Steel, Hastelloy (C22)

Cooling: Double Jacket

Mixer: VISCOPROP or GASJET

Pharma Design: GMP and Good Cleanability

Cleaning: Includes Cleaning-in-Place (CIP)

Qualification: IQ and OQ

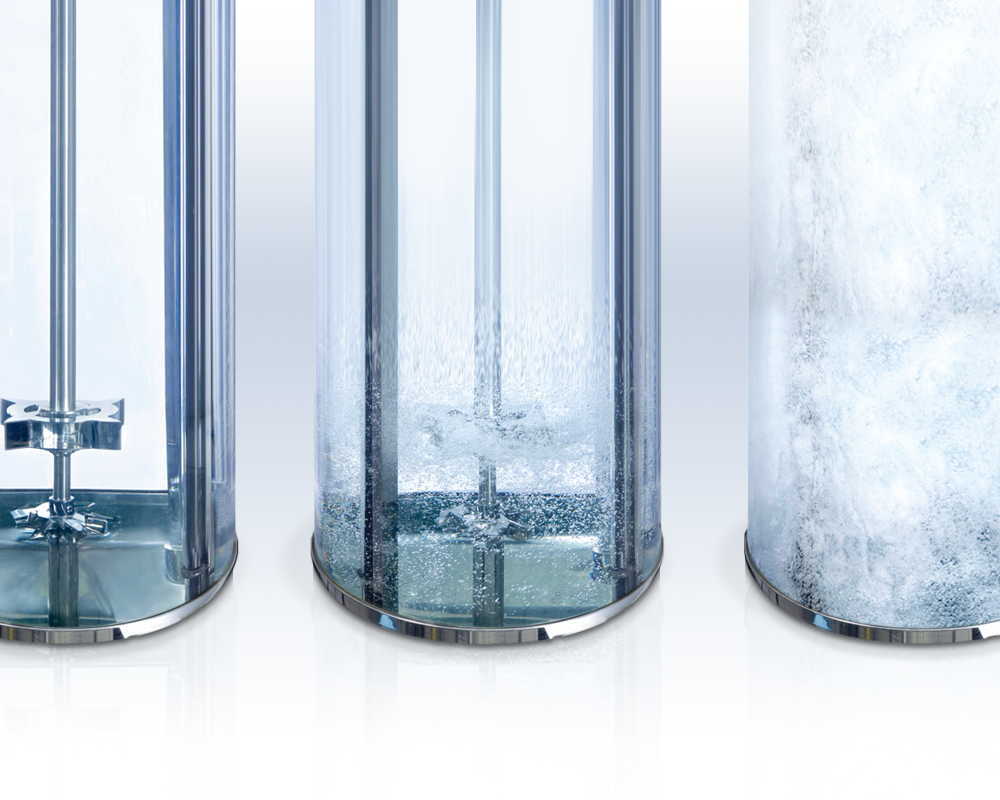

Gas-Liquid Reactor with Interchangeable Impeller System

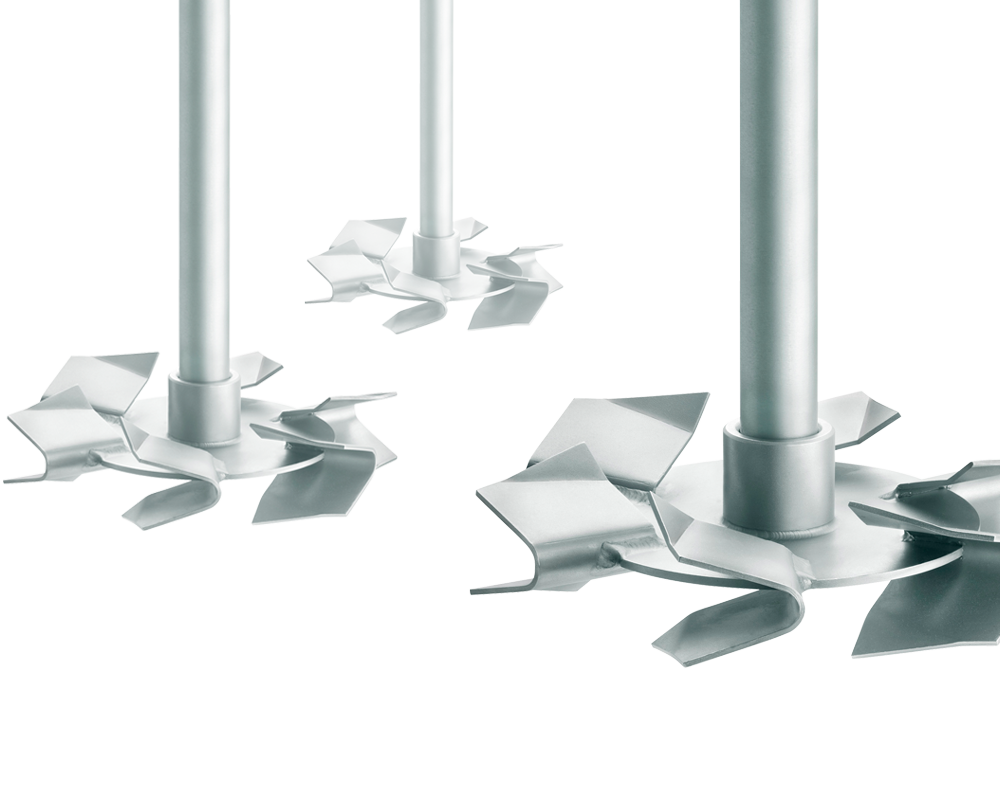

Self-Aspirating turbine for volume gassing:

GASJET

- Self-aspirating impeller

- Draws gas through hollow shaft

- Re-disperses gas

- Gas is finely dispersed into liquid

- Improves mass transfer

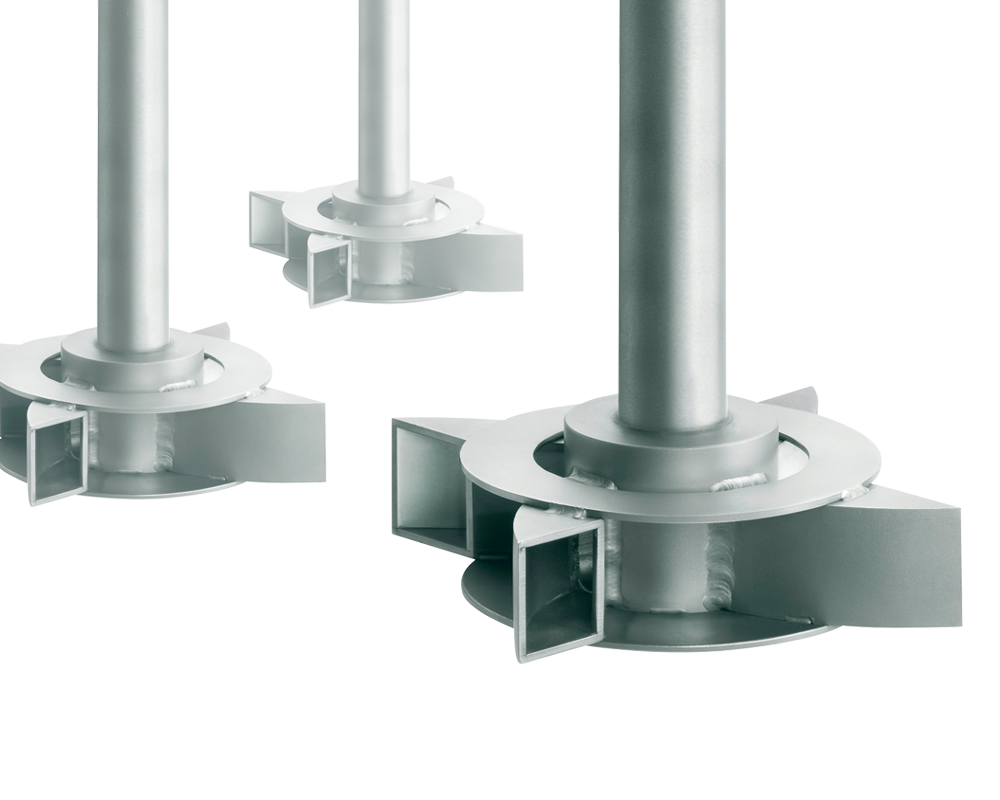

PHASEJET

- Eliminates flat blade turbine issues under gas

- Blades shaped to reduce flow separation

- Stable power draw (gassed vs. ungassed)

- Over 2× higher flooding limit

- Boosts overall efficiency

EKATO GASJET Impeller for gas-liquid applications with pure gases -18

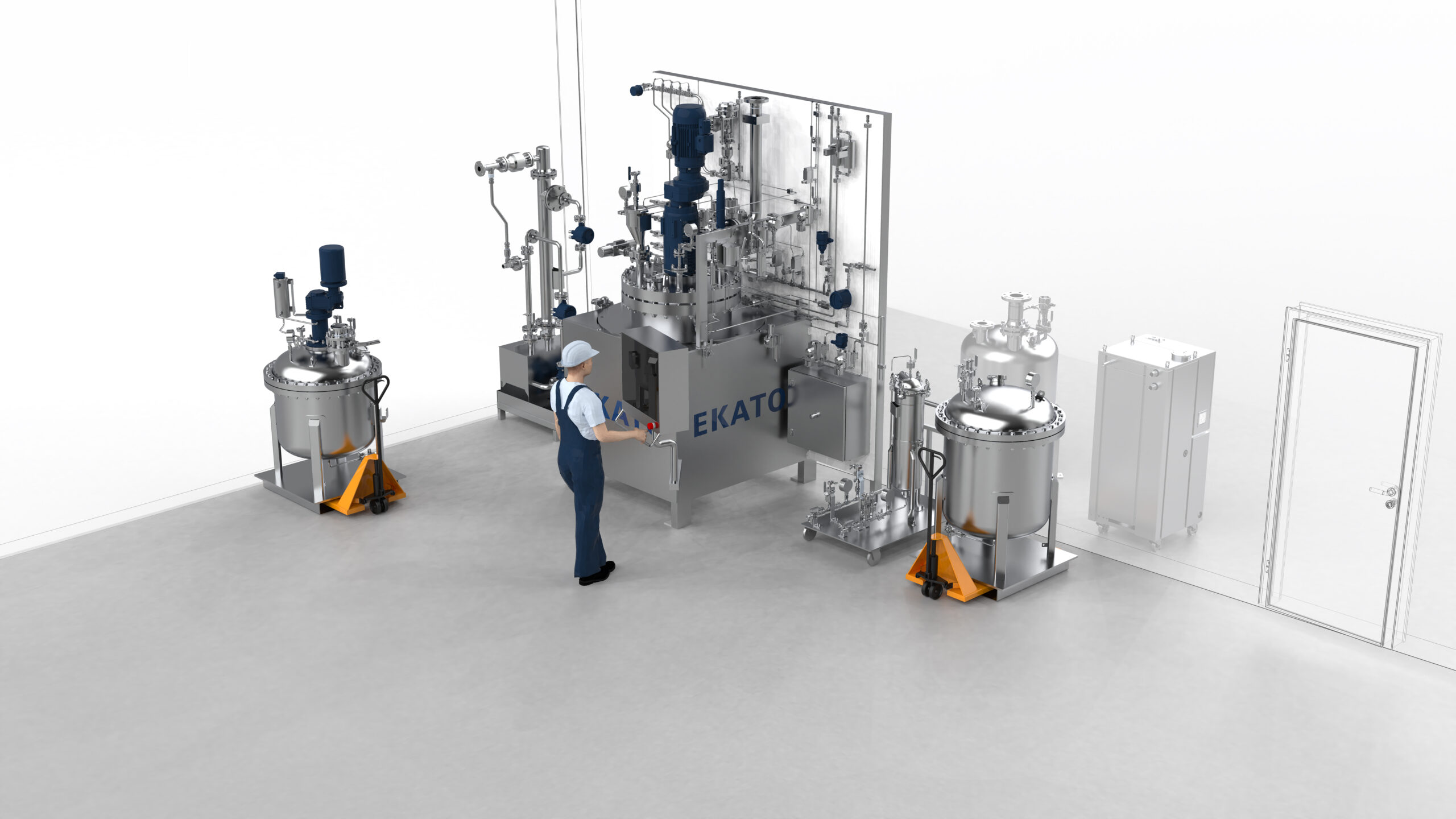

Modular Process Components

Preparation Tank

- Moveable via palette trucks

- Agitator for suspending / dissolving Solids

- Available in different volumes / materials

- Optional lock for catalyst loading

Pump Station

Filter

Transfer Tank

Heating / Cooling Unit

Scrubber

Knock Out / Blow Out

Small-Scale Hydrogenation Unit

Transforming Production with Compact Modularity

- Advanced, modular hydrogenation plant tailored for pharmaceuticals (e.g. Active Pharmaceutical Ingredients (APIs), Active Diagnostic Ingredients (ADIs), small molecules, Drug Substances

- Hygienic design enables safe cleaning and prevents product cross-contamination and avoids irregular FDA audits

- Modular design allows for customizable configurations, providing tailored solutions for your production

- Designed for small and medium batch sizes

- Exceptional process flexibility and efficient production for various quantities

- Equipped with advanced safety mechanisms and automated controls for precise production processes