Efficiency Screening – A New EKATO Service

Optimize. Modernize. Save.

Senior Process Consultant

EKATO Rühr- und Mischtechnik GmbH

.

Process Consultation

Contact us today to connect directly with our Sales Project Manager and discover how we can enhance your process, equipment, and overall plant efficiency.

What Is EKATO Efficiency Screening?

Efficiency Screening is a comprehensive on-site or remote assessment conducted by EKATO specialists. It focuses on evaluating the performance of your agitated reactors and identifying opportunities for:

- Energy Savings

- Process Optimization

- Equipment Modernization

This service is tailored to your plant’s unique setup, ensuring that recommendations are practical, impactful, and aligned with your production goals.

Key Benefits and Optimization Areas

Energy Efficiency

Agitation systems are often overlooked when it comes to energy efficiency. EKATO’s screening can reveal:

- Oversized or underperforming agitators

- Inefficient mixing patterns

- Opportunities for motor downsizing or speed adjustment

Result: Lower energy bills and reduced carbon footprint—without compromising process quality.

Process Optimization

Efficiency Screening dives deep into your process parameters to identify improvements in:

- Batch Time Reduction: Faster mixing and reaction times.

- Heating/Cooling Efficiency: Improved heat transfer through optimized flow patterns.

- Mixing Quality: Enhanced homogeneity, suspension, dispersion or emulsification.

Result: Increased throughput, improved product consistency, and reduced operational costs.

Mechanical Improvements and Maintenance

EKATO’s Efficiency Screening also evaluates the mechanical integrity of your mixing equipment. This includes assessing wear and tear, checking for signs of fatigue, and reviewing maintenance practices. Based on the findings, EKATO may recommend upgrades such as

- improved bearings and enhanced sealing systems

- optimized maintenance schedules

- installation of preventive maintenance

These measures help extend the life of your equipment, reduce unexpected downtime, and ensure reliable long-term performance.

Customization & Modernization

EKATO’s experts assess whether your current equipment is still fit for purpose. If not, they’ll recommend:

- Retrofitting existing agitators

- Upgrading to modern mixing technologies

- Custom-designed solutions for new or evolving processes

Result: Future-proofed operations with equipment that matches your process needs.

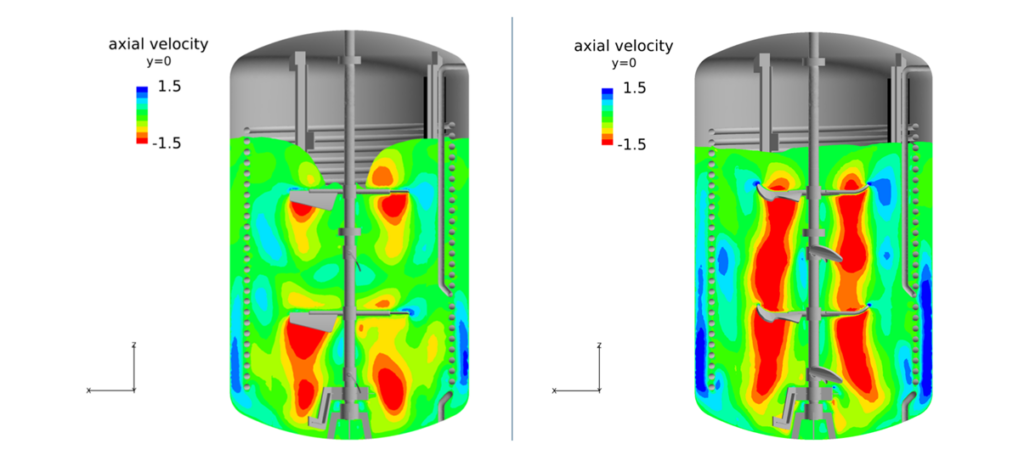

Success Stary - Comparison of two diferent mixing systems

How It Works & Why EKATO

The Screening Process

Why Choose EKATO?

- Decades of Expertise in mixing technology across industries

- Tailored Solutions for chemical, pharmaceutical, cosmetic, and food sectors

- Global Reach with local support and engineering teams

- Sustainability Focus through energy-efficient designs and process improvements

Ready to Discover Your Plant’s Hidden Potential?

Contact EKATO today to schedule your Efficiency Screening and take the first step toward smarter, more efficient operations.