Process Units for Solids - SOLIDMIX

EKATO SOLIDMIX Main Industries

Sustainability

By definition, an appliance alone cannot be described as sustainable. However, an apparatus solution that helps to optimize your manufacturing process makes your process demonstrably more “sustainable”. Long before the label “sustainability” existed, EKATO was already dedicated to optimizing processes through optimum agitator technology:

- Minimization of energy contributions in the process. (energy balance)

- Reduction in the use of raw materials through better process engineering.

- Simplification of equipment solutions through the use of one-pot systems

When optimizing your process, we can draw on experience from the above-mentioned industries – and look beyond the edge of the plate.

Your process developed through the use of EKATO technology and experience proudly deserves the label “sustainable”.

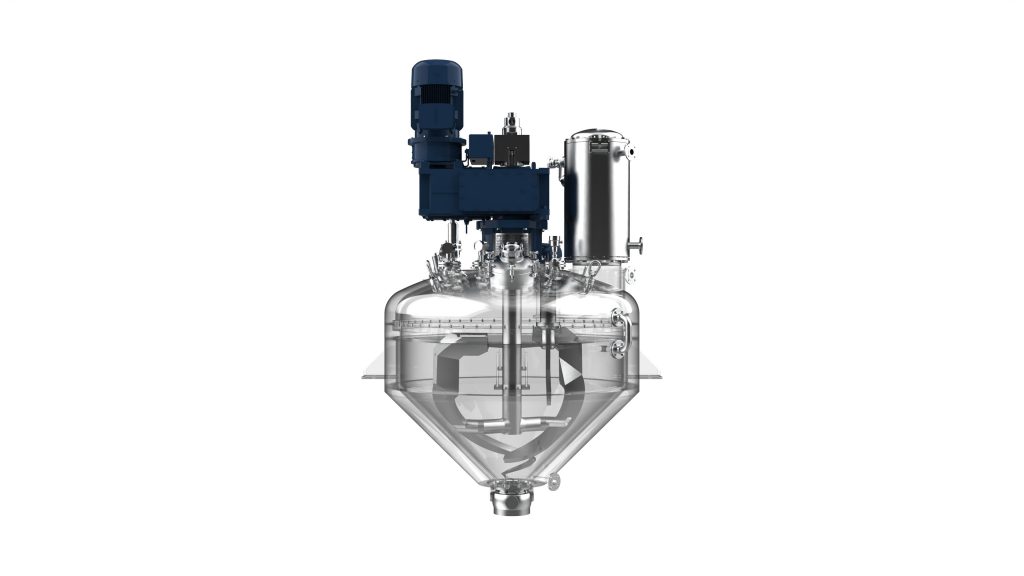

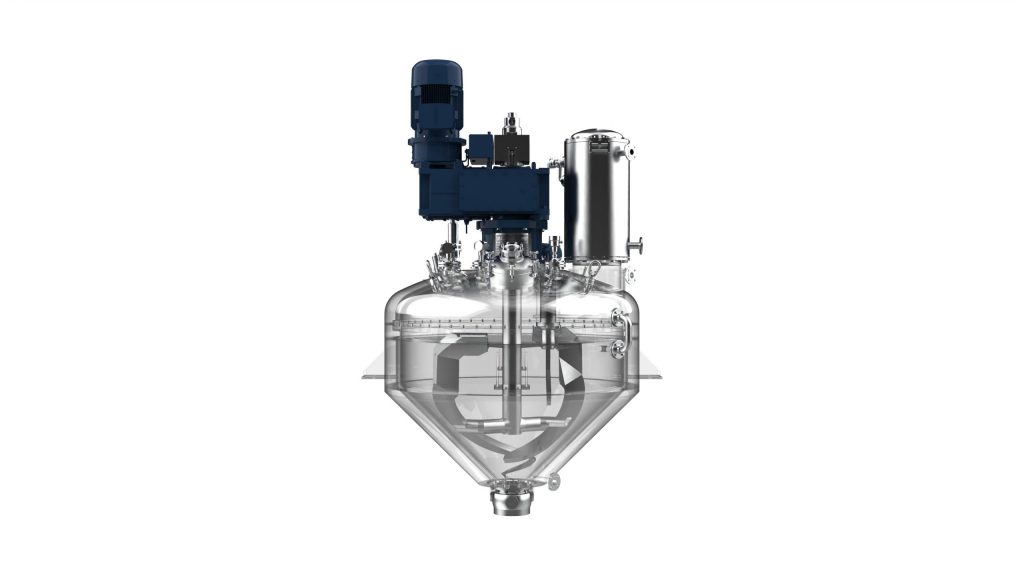

EKATO SOLIDMIX Impeller Systems

For free-flowing solids or large apparatus volumes, the SOLIDS-PARAVISC impeller is used in the SOLIDMIX VST series. The ISOPAS impeller was designed for processing pasty, high viscous media, or for applications where the discharge behavior of the products requires an agitator system with minimal wetted surfaces.

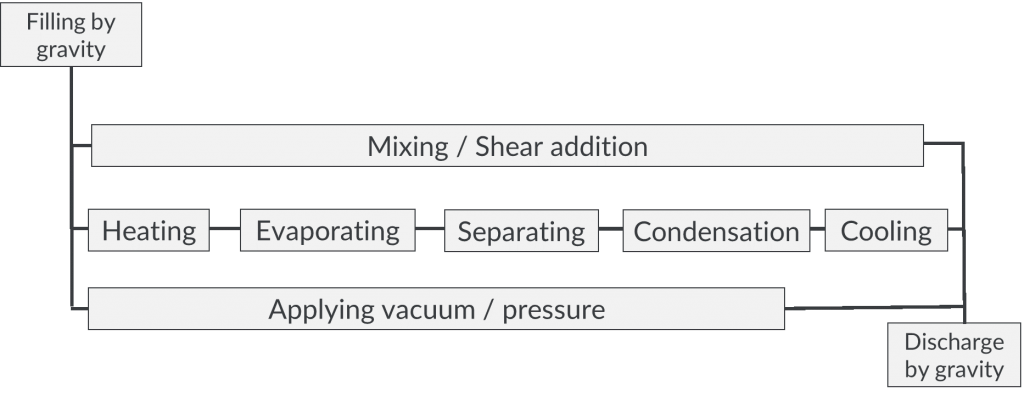

Overview of the basic process operations in an EKATO SOLIDMIX systems

Vacuum contact drying of solids from a centrifuge, nutche or decanter

A conical vacuum contact dryer is extensively used in the pharmaceutical, chemical, and food industries for its highly efficient drying capabilities and versatility. Key processes within this dryer include mixing, drying, and solvent recovery. The conical shape is designed to promote uniform mixing and drying by ensuring thorough contact between the product and the heated surfaces.

EKATO SOLIDMIX 360° For mixing and drying of bulk solids 15

The application of vacuum reduces the boiling point of solvents, allowing for gentle drying at lower temperatures. This is especially advantageous for heat-sensitive materials, preserving their quality and integrity. The rotating motion of the dryer further enhances mixing, ensuring even heat distribution and preventing agglomeration of the product.

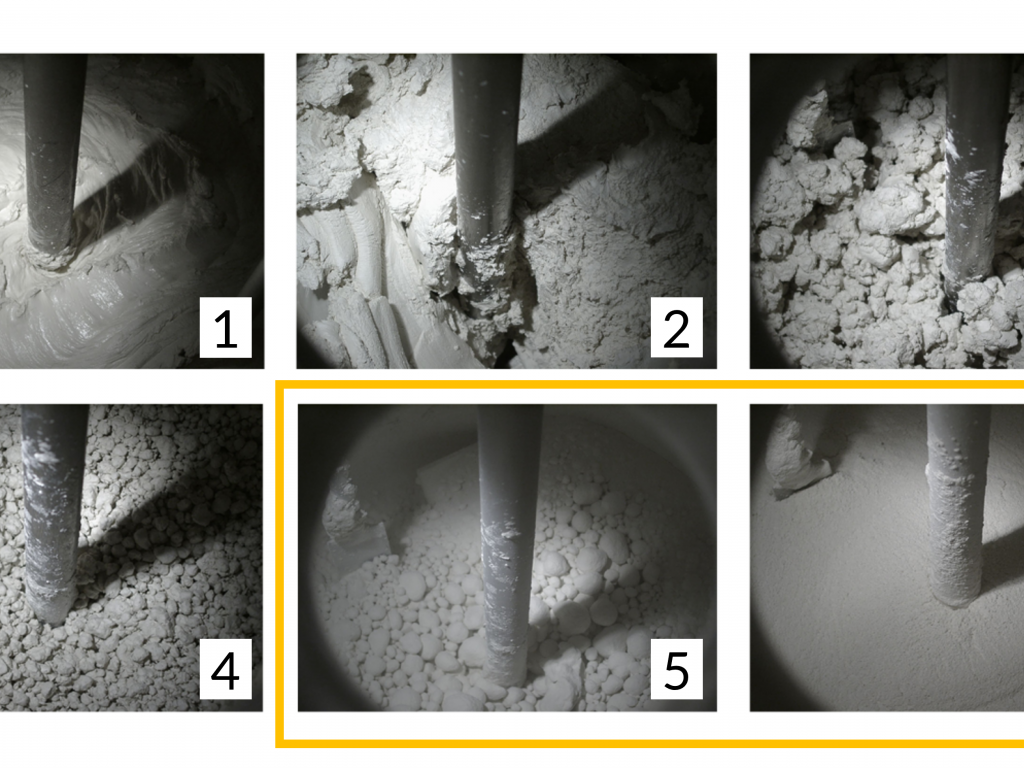

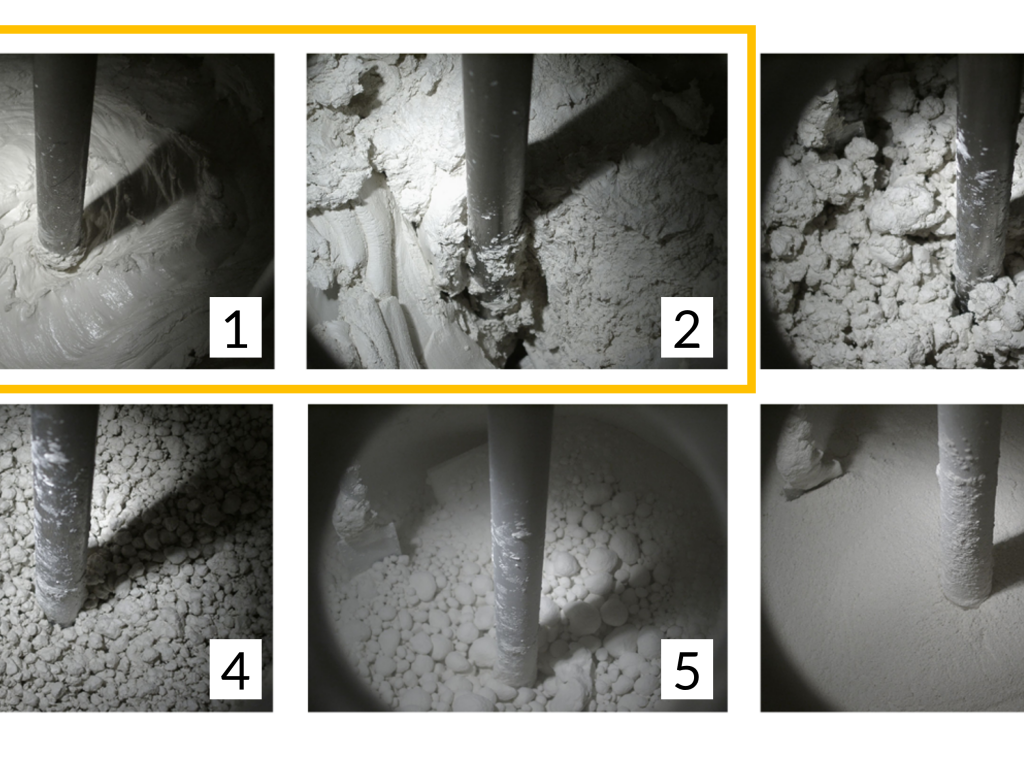

The typical product appearance in a conical vacuum dryer:

1…2: Liquid due to extractions or chemical reactions ~ 90% solvents

3…4: Pasty filter cakes ~ 50% solvents

3…5: Moist material from centrifuges, nutche, decanter ~ 40% solvents

6: Spray dried powder for post drying ~ 8% solvents

Your EKATO SOLIDMIX benefits:

- Reliability for your process all the way from small-scale trials to operating systems thanks to years of experience

- Practical solutions developed by experts from the field and basic researchers

- EKATO is your partner throughout the entire lifecycle of your application

Fed-batch-vacuum drying of solutions with a low solids content

The versatile agitator technology in the EKATO SOLIDMIX dryer allows the evaporation of slurries with a low solids content with the aim of concentration. Once the mass has been concentrated by adding slurry during the condense process, efficient drying can be started. The concept works with a continuous supply of slurry – the “fed-batch process”.

Typical applications: aroma extraction from leaves with a low solids content in the solution.

Your EKATO SOLIDMIX benefits:

- Reliability for your process all the way from small-scale trials to operating systems thanks to years of experience

- The one-vessel process reduces the amount of equipment required and cuts installation costs

- EKATO is your partner throughout the entire lifecycle of your application

Vertical drying system with spray-on devices for impregnation

- Automotive catalysts

- Decorative sugars

- Coatings for bulk materials

Your EKATO SOLIDMIX benefits:

- Reliability for your process all the way from small-scale trials to operating systems thanks to years of experience.

- Dust-free processes are possible with EKATO technology. The advantage for the operator and the environment

- EKATO is your partner throughout the entire lifecycle of your application.

Chemical reactions under addition and removal of heat, under overpressure and vacuum

Your EKATO SOLIDMIX benefits:

- Reliability for your process all the way from small-scale trials to operating systems thanks to years of experience

- Benefit from the process knowledge of the EAKTO Group – transferred to your solids material application

- EKATO is your partner throughout the entire lifecycle of your application

Vertical kneaders for mixes with a high solids content

Your EKATO SOLIDMIX benefits:

- Reliability for your process all the way from small-scale trials to operating systems thanks to years of experience.

- EKATO mixers can improve product quality. Test your materials on an EKATO mixer

- EKATO mixers result in short mixing times and reduce your operating costs

Vertical drying systems for spray-dried solids

Your EKATO SOLIDMIX benefits:

- Reliability for your process all the way from small-scale trials to operating systems thanks to years of experience.

- EKATO mixers can improve product quality. Test your materials on an EKATO mixer

- EKATO mixers result in short mixing times and reduce your operating costs

Heating / Cooling

Vessel heating or cooling is essential in many industrial processes, with various methods ensuring efficient and uniform temperature control. Three common techniques include double jackets, dimple jackets, and half-pipe coils. EKATO SOLIDMIX dryers and reactors, great importance is attached to heating or cooling that is adapted to the process. In theory and in practice. The transfer of heat and cold via the vessel wall into an agitated solid bulk material requires optimum conditions and is limited by the internal heat transfer. The circulation of a heat transfer fluid has proven itself in solid applications. 43

Your EKATO SOLIDMIX benefits:

Reliability for your process all the way from small-scale trials to operating systems thanks to years of experience.

EKATO assumes responsibility for the process-relevant components itself

EKATO is flexible and can take your proven suppliers into account

Evaporation and Condensation = Solvent recovery

Solvent recovery is a critical process. Evaporated solvents are condensed and collected, allowing for their reuse and making the process environmentally friendly and cost-effective. This capability not only conserves resources but also reduces operational costs. Overall, a conical vacuum contact dryer provides efficient drying, maintains high product quality, and delivers significant energy savings, making it a preferred choice in various industries.

A EKATO SOLIDMIX solvent recovery system includes components such as a pre-condenser, post-condenser, and a vacuum pump. The pre-condenser is positioned before the vacuum pump to cool and condense a large portion of the solvent vapors, reducing the load on the vacuum pump and enhancing overall efficiency. The post-condenser, located after the vacuum pump, captures any remaining solvent vapors, ensuring maximum recovery and preventing emissions. This two-stage condensation approach significantly improves solvent recovery rates. The vacuum pump is crucial for creating the necessary vacuum conditions without contaminating the solvents with oil or other lubricants, maintaining the purity and quality of the recovered solvents. Overall, these systems are vital for optimizing solvent usage, reducing operational costs, and adhering to stringent environmental regulations. EKATO SOLIDMIX designs and builds both the dryers and the solvent recove

Your EKATO SOLIDMIX benefits:

Reliability for your process all the way from small-scale trials to operating systems thanks to years of experience.

EKATO assumes responsibility for the process-relevant components itself

EKATO is flexible and can take your proven suppliers into account

Separation – Dust filter systems

EKATO builds the systems “technically tight”. This makes it necessary to enable ventilation during filling and emptying. Whether a pendulum line or breathing filter – EKATO has the right solution in its range.

Any pressure equalization can lead to the entry of foreign bodies into the process chamber (microbes, micro dust). Product dust can enter the vent line during depressurization. The use of HEPA filters has proven its worth here.

High vapor flows occur during vacuum drying. Here it is important to separate the vapors from the entrained dust and leave the dust in the container. This must not result in significant pressure losses. The EKATO dust filter systems are specially designed for use in dryers. Many years of operating experience confirm the concept in practice.

Your EKATO SOLIDMIX benefits:

Reliability for your process all the way from small-scale trials to operating systems thanks to years of experience.

EKATO assumes responsibility for the process-relevant components itself

EKATO is flexible and can take your proven suppliers into account 49

Process Auxiliaries (Chopper, Yield Blade, Nitrogen Purge)

The EKATO SOLIDMIX dryers and reactors can be supplemented with additional functions:

Chopper:

Both the EKATO PARAVISC and the EKATO ISOPAS are regarded as gentle mixing systems. If high shear forces are required in the process (e.g. for granulation processes or to avoid lump formation), the EKATO chopper can be used. A remote agitator installed from above, equipped with a knife mechanism, introduces controlled shearing into the solid’s mixture. The shearing effect can be controlled by a frequency converter.

Your EKATO SOLIDMIX benefits:

- Reliability for your process all the way from small-scale trials to operating systems thanks to years of experience.

- EKATO assumes responsibility for the process-relevant components itself.

- With the EKATO modular system, extensions are possible even years after commissioning

Yield Blade

The container shape of the SOLIDMIX dryers and reactors – upright with a conical bottom – is already designed for high discharge rates. However, heavy-flowing (dry) solids often adhere to the vessel surfaces or agitator elements. The EKATO Yield blade is a non-contact dedusting technology. A targeted nitrogen pulse loosens the build-up layers and supports the outflow.

sumes responsibility for the process-relevant components itself.

With the EKATO modular system, extensions are possible even years after commissioning

Nitrogen purge/sweep

If vacuum drying is diffusion-driven, this results in very long drying times. The addition of a defined flow of an inert gas led to a change in the partial pressure around the solid grain – this accelerates the diffusion process. EKATO has the pilot plant facilities with which this effect can be demonstrated. With the data obtained, it is then possible to design a flushing system for the plant size – also as a retrofit for existing dryers.

Your EKATO SOLIDMIX benefits:

Reliability for your process all the way from small-scale trials to operating systems thanks to years of experience.

EKATO assumes responsibility for the process-relevant components itself.

With the EKATO modular system, extensions are possible even years after commissioning

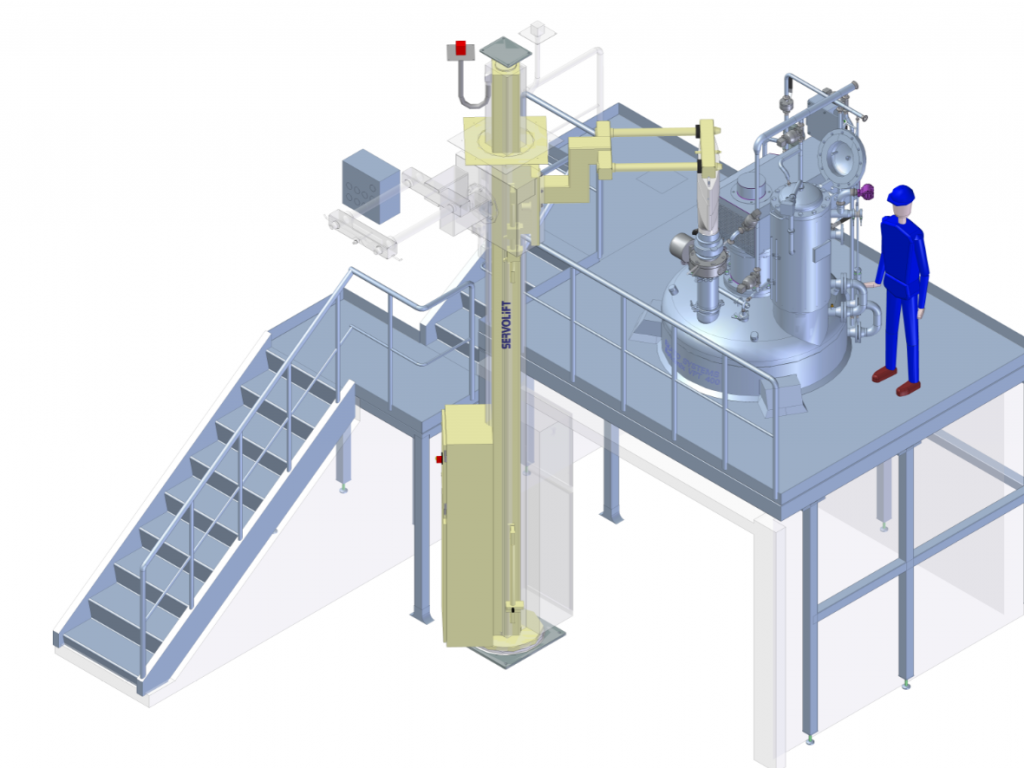

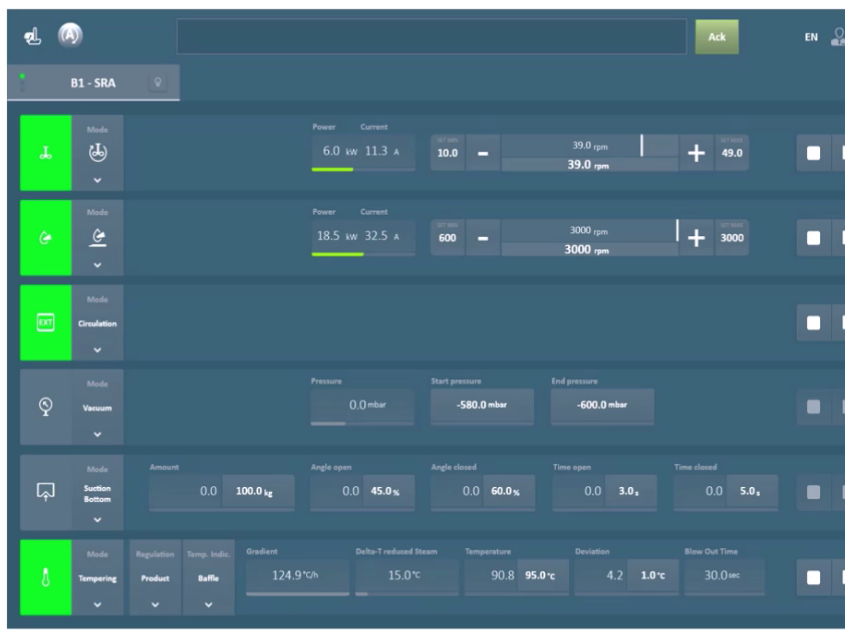

All EKATO SOLIDMIX drying, and reactor systems are delivered fully automated and commissioned by us. As a result, the responsibility for process success and mechanical integrity remains in one hand. 57

Process benefits:

EPOS – EKATO Process Operating System

Small scale testing and scale up

- Recording, visualization & trending

- Dynamic information system (P&ID)

- Alarm list with analytical functions

- Calibration tool

- Maintenance information

- Network data transfer

- Fully automated production possible

Data management benefits:

User management

Electronical Signature

Batch Report

Audit trail

Data integrity – tamper proof

Continuous traceability

Online documentation

Regulations (standards met):

GAMP 5 and FDA CFR Part 11

Programming standard acc. ISA-88

Recipe system in relation to ISPE GAMP5

Ready to connect interfaces: OPCUA / SAP / SQL

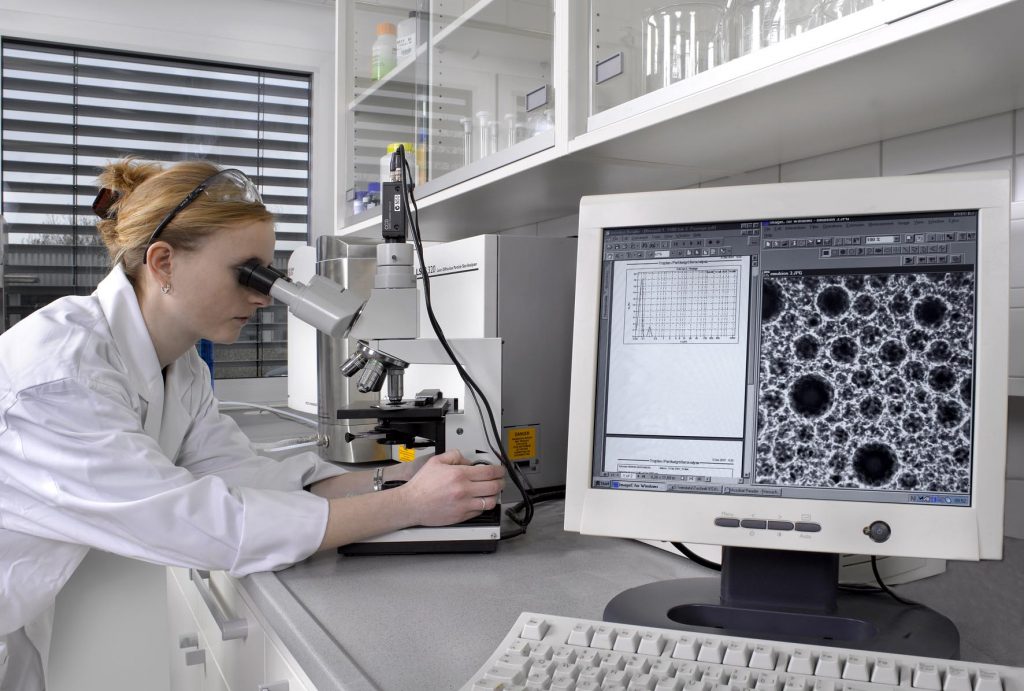

Although EKATO has many years of experience in the design and extrapolation of solids processes, we can offer you an application laboratory for testing purposes. Here we can prove the suitability of your system on a scale between 3 liters and 100 liters and support you in the development of your new processes. Mobile systems are available for hire for on-site trials.

| Pilot Plant Type and Model | Type | Working Volume | Process | Product |

|---|---|---|---|---|

| EKATO SOLIDMIX VPT 3 | Vertical Process Mixer / Dryer Lab Scale | 3 Liter | Mixing, Blending, Drying, Reaction, Spraying | Solids, Pasty Mixtures, Powders, Granulates e.g. APIs, Base Chemicals, Pigments, Food Stuff |

| EKATO SOLIDMIX VPT 25 | Vertical Process Mixer / Dryer Pilot Scale | 25 Liter | Mixing, Blending, Drying, Reaction, Spraying | Solids, Pasty Mixtures, Powders, Granulates e.g. APIs, Base Chemicals, Pigments, Food Stuff |

| EKATO SOLIDMIX VPT 50 | Vertical Process Mixer / Dryer Pilot Scale | 50 Liter | Mixing, Blending, Drying, Reaction, Spraying | Solids, Pasty Mixtures, Powders, Granulates e.g. APIs, Base Chemicals, Pigments, Food Stuff |

| EKATO SOLIDMIX VST 5 | Vertical Solids Mixer / Dryer Lab scale | 5 Liter | Mixing, Blending, Drying, Reaction, Spraying | Solids, Pasty Mixtures, Powders, Granulates e.g. APIs, Base Chemicals, Pigments, Food Stuff |

| EKATO SOLIDMIX VST 50 | Vertical Solids Mixer / Dryer Pilot scale | 50 Liter | Mixing, Blending, Drying, Reaction, Spraying | Solids, Pasty Mixtures, Powders, Granulates e.g. APIs, Base Chemicals, Pigments, Food Stuff |

| EKATO SOLIDMIX VST 100 | Vertical Solids Mixer / Dryer Pilot scale | 100 Liter | Mixing, Blending, Drying, Reaction, Spraying | Solids, Pasty Mixtures, Powders, Granulates e.g. APIs, Base Chemicals, Pigments, Food Stuff |