UNIMIX Vacuum Processing System

Personal care, cosmetics, pharmaceutical, chemical and food industries

Mixing and homogenizing = EKATO UNIMIX

This is the formula for your success. EKATO UNIMIX system technology offers all functions for the manufacture of complex products from many branches of industry, from laboratory to production scale.

Vacuum process mixers are often used in the cosmetics and pharmaceutical industries to produce large product ranges. From emulsions to gels, from products with low to high viscosity, producing partial to complete batches – vacuum process mixers must be suitable for a wide range of manufacturing conditions while achieving a high level of quality.

Although conventional production technology would be able to manufacture the products, it is often not possible to achieve the required product quality in the required time. The basis for consistently high product quality in the EKATO UNIMIX systems is the interaction of homogenizer and agitator. This combination enables the necessary process steps and product requirements to be optimally implemented and fulfilled.

Product details

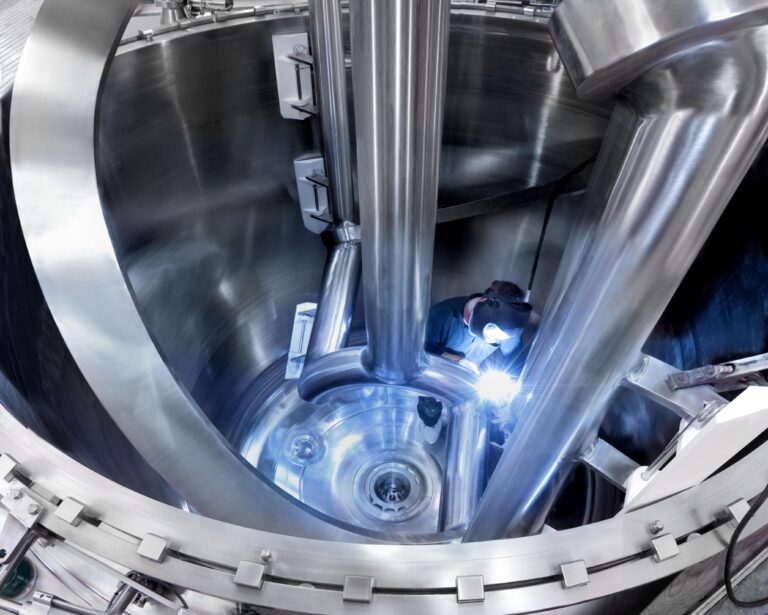

With the UNIMIX product line, EKATO SYSTEMS offers “state of the art” laboratory mixers, pilot mixers and production mixers. The scope of delivery can range from a single system to a complete process system.

The UNIMIX system includes the following components, among others:

- Patented EKATO PARAVISC agitator (mixing and stirring)

- EKATO S-JET homogenizer (homogenizing)

- Automation

- Vacuum and pressure vessels according to ASME, PED, or SELO

- Heating and cooling function

- Cleaning in place (CIP) cleaning system

The combination of agitator and homogenizer is crucial for the mixing process. With their process engineering advantages, all systems in this series guarantee the fast, safe and economical production of a variety of products with different viscosities (e.g. lotions, creams, gels, toothpaste, mascara).

The UNIMIX main components at a glance

EKATO PARAVISC agitator

The EKATO PARAVISC agitator is characterized by excellent axial mixing and is very versatile in the mixing process.

- Short mixing times and very good wall heat transfer across the entire viscosity range

- Open design enables the use of a central baffle

- Use of wall scrapers to reduce wall boundary layers and optimize heat transfer

EKATO S-JET Homogenizer

The EKATO S-JET is not only designed for general homogenizing tasks, but also meets the highest requirements in solids dispersion.

- Designed for internal homogenization within the tank, as well as for external homogenization via the recirculation line

- Switching from 100% internal to 100% external homogenization via magnetic adjusting ring

- Large quantities of powder are sucked directly into the homogenizer, enabling the shortest process times with the highest product quality

- Automated product infeed for reproducible product quality

- Generates high pressure for the circulation and discharge of highly viscous products

- No additional pump required, the EKATO S-JET is used for discharging the product and also as a CIP pump

Additional EKATO S-JET design features

- Internal homogenization enables even the lowest fill levels

- Direct suction of liquids and/or solids into the shear gap for immediate wetting and dispersion

- Double-acting mechanical seal unit for easy installation/removal

- No dead zones on the shaft, as the seal rings on the product side are directly connected to the rotor

- Integration of the suction rate into the automation enables full process control

- Automated sealing liquid system with pressure and fill level control

- cGMP compliant design

- Ideal interaction with the agitator (EKATO PARAVISC) for efficient product circulation in the container

- S-JET/V: Especially for toothpaste and other products with high throughput

UNIMIX vacuum processing systems are used worldwide and enjoy an excellent reputation in the production of ointments, gels, creams, suspensions, toothpaste, skin care products, decorative cosmetics and a number of products in the food and chemical industries.

Special features

- Ideal vertical and radial mixing thanks to the EKATO PARAVISC agitator

- Immediate dispersion of raw materials when added via the UNIMIX S-JET homogenizer

- Short-circuit-free internal/external product recirculation

- Variable shear energy input

- Optimum heating and cooling times

- Reinigung an Ort und Stelle (CIP)

Vacuum process plant type UNIMIX SRA (100 L to 10,000 L)

Vacuum processing system type UNIMIX SRC with lifting column (100 L to 10,000 L)

Large scale systems > 10,000 liters batch volume

UNIMIX can here support with:

- Batch time analysis per product or product group

- Productivity and Capacity calculations

- Process engineering and material handling consulting

- Engineering and construction of large batch plants

Together with our customers, we determine the benefits.

Talk to us.

Pilot plant mixer type UNIMIX SRT 50

The UNIMIX SRT series of pilot plant mixers was designed for product and process development (scale-up) in the pharmaceutical and cosmetics industries. This machine type is characterized by its particularly compact design and can be put into operation immediately. All components/operations are identical to the production systems:

- EKATO PARAVISC agitator

- EKATO S-JET homogenizer

- Automation

- Heating and cooling

- Cleaning (CIP)

- Vacuum pump

Laboratory mixer type UNIMIX LM (6 L) for product development

UNIMIX PRELIMINARY PHASES

- Fastest possible heating and melting of oils with pellet and block waxes.

- Effective size reduction and surface enlargement by milling without damaging the agitators.

- Efficient agitator for water phases with technology for Powder wetting.

- Optionally with integrated, self-sufficient CIP-System.

The preparation time for the preliminary phases is optimized up to 40%.

The preliminary phases are fully integrated into the EKATO Prozess Operations System EPOS can be integrated with all available modules. This means that different production statuses and situations can be batch number related and documented and archived in a traceable log format. CFR21 Part 11.

Also in the prefabrication program of EKATO available with fast availability – very cost-efficient.

EKATO –Pre-phase container with PRE-JET

- Preliminary phases shorten their batch times by up to 50%.

- You save energy.

- You gain flexibility.

- Reduce cleaning effort and resources.

We calculate batch times for you or simulate production capacities with EKATO UNIMIX Systems with pre-phase tanks.

UNIMIX Prefabrication

UNIMIX HYDS

High Yield Discharge (HYD) in cosmetic production refers to the efficient emptying of production equipment to ensure that as much of the manufactured product as possible is removed from the container or machine. This is particularly important to minimize losses and maximize production efficiency. Here are some aspects and benefits of High Yield Discharge in the cosmetics industry:

- Conservation of resources: Effective emptying makes optimum use of raw materials, which lowers costs and reduces material consumption.

- Product quality: Complete emptying prevents the mixing of batches and ensures that the quality of the end product remains constant.

- Cleaning effort: Less residue in the container means less cleaning between production runs, which saves time and resources.

- Increased efficiency: A high yield during unloading leads to better overall efficiency of the production process, as less time is needed for refilling or cleaning.

- Technological solutions: The use of modern technologies such as vacuum or pressure systems can help to optimize the unloading process and maximize yield.

- Sustainability: A higher yield contributes to sustainability by reducing waste and environmental impact.

Overall High Yield Discharge an important aspect in the production of decorative cosmetics, which offers both economic and qualitative advantages and contributes to increased efficiency.

UNIMIX HYDS – efficient with pressure

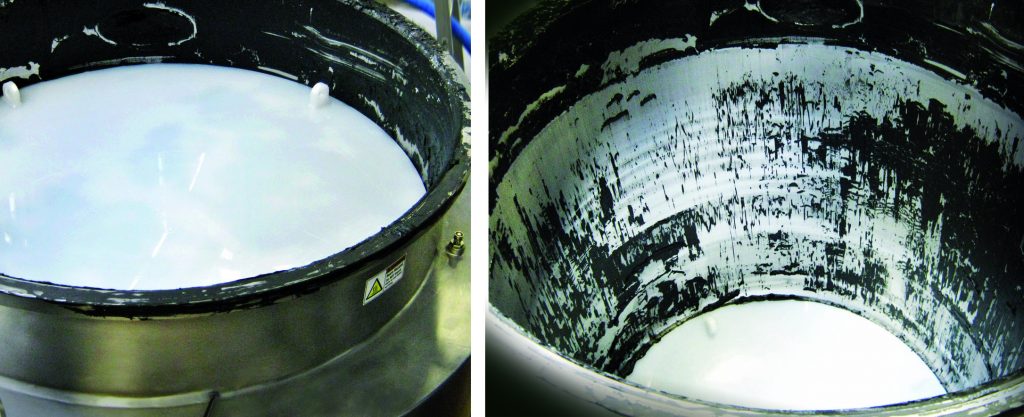

Procedure

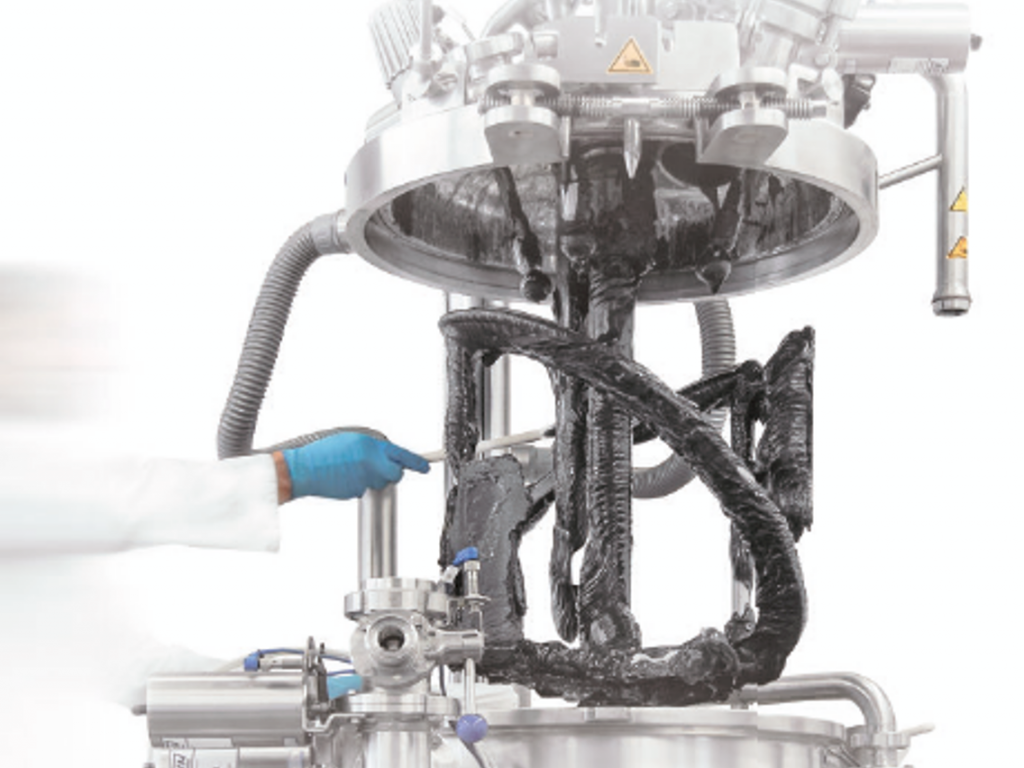

- Open container

- Scrape off agitator residue manually

- Turn the lid with agitator to the side

- Use High Yield Discharge Disc

- Cover the container with a secondary lid

- Apply pressure and empty

Highest exploitation rates (>98%)

- Increases productivity

- Saving raw materials

- Reduces cleaning costs