Consulting, Engineering, Modernization (CEM)

Your Processes are Developing- What About your Machines?

Consulting, Engineering and Modernization Your processes are developing, what about your plants?

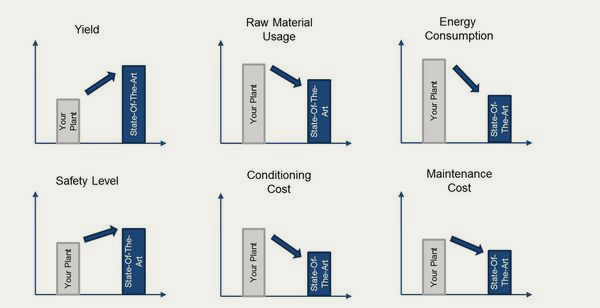

Process Evaluation

The process evaluation enables the detection of:

- Time savings: e.g. through faster mass transfer. Ideally, this leads to shorter batch times and more production capacity (increase in the number of batches).

- Energy efficiency: e.g. by saving process air or compressor power or expensive pure gases

- Quality improvement: e.g. through efficient educt conversion. An optimized set-up of agitation technology and reactor vessel helps improve product quality or prevents undesired side reactions

The mechanical components can often also be improved

- Increased operational safety: e.g. due to lower mechanical loads after the installation of an optimized mixing system

- Reduced maintenance time: e.g. by retrofitting a lifting and swivel device for efficient seal exchange

- Extended service life: e.g. through condition-based maintenance cycles and an optimized agitator design

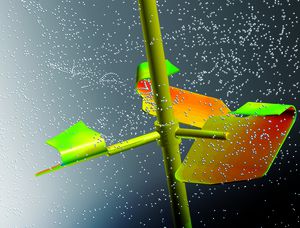

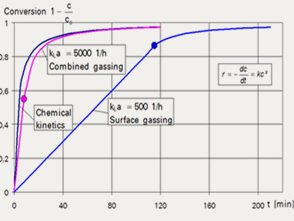

Time Savings: EKATO Combined Gassing System

| Existing | New | |

|---|---|---|

| Reaction time | 3.5 h | 2.0 h |

| Filling/Emptying/Heating | 2.0 h | 2.0 h |

| Batch time | 5.5 h | 4.0 h |

| Batches/Year | 1,450 | 2,000 |

550 additional batches >>4400 t additives per year

- Same motor power - reduced power consumption per kg

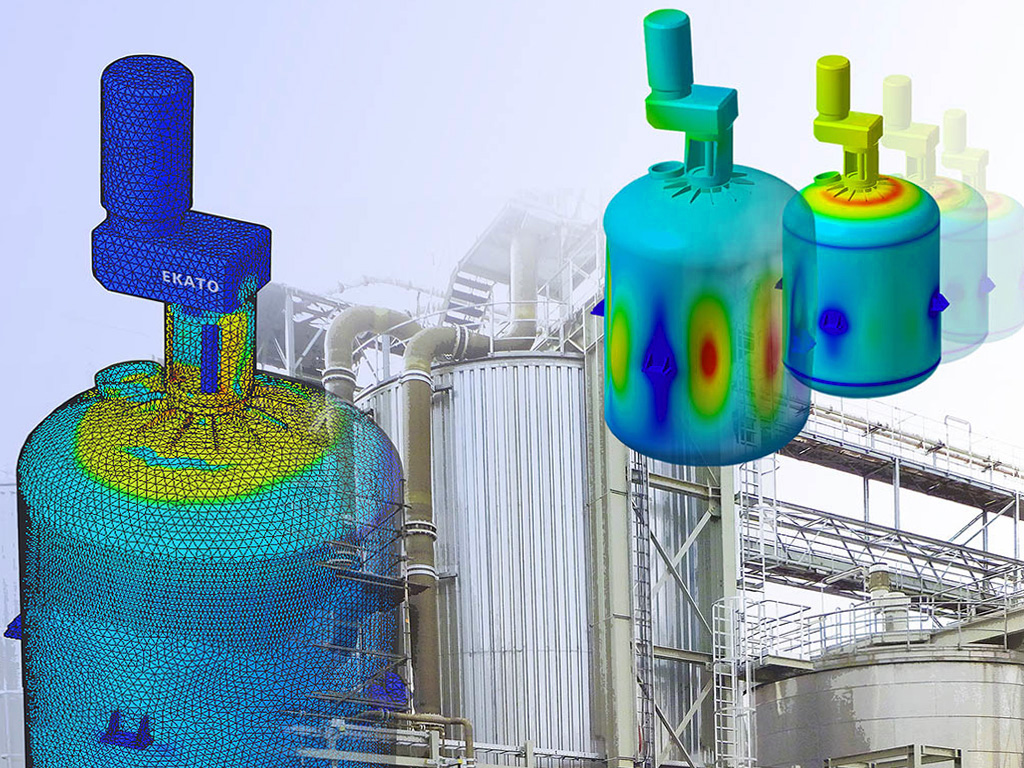

Engineering Study: Verification of New Process Parameters

In the field of basic chemicals, agitators with a service life of >30 years are not uncommon. Many parameters can change in such a long period of time. The agitator usually remains untouched. However, it is still worth having it checked!

The agitated product has a direct influence on the mechanical loads on the agitator and the vessel. A change in density or viscosity has an influence on the mechanical forces and loads. EKATO CEM supports you in the validation of your agitator and helps to ensure safe operation. Such a validation includes a complete mechanical check, including parameters like shaft safety, bearing life or nozzle loads. If required, the agitator can alse be checked for process design.

The results of this work will be summarized in a report and made available for you. The cost for such a study is small, compared with the costs that come along with a breakdown and downtime. Should the results of the study show that the agitator is mechanically insufficient, it will be the basis for an retrofit offer.

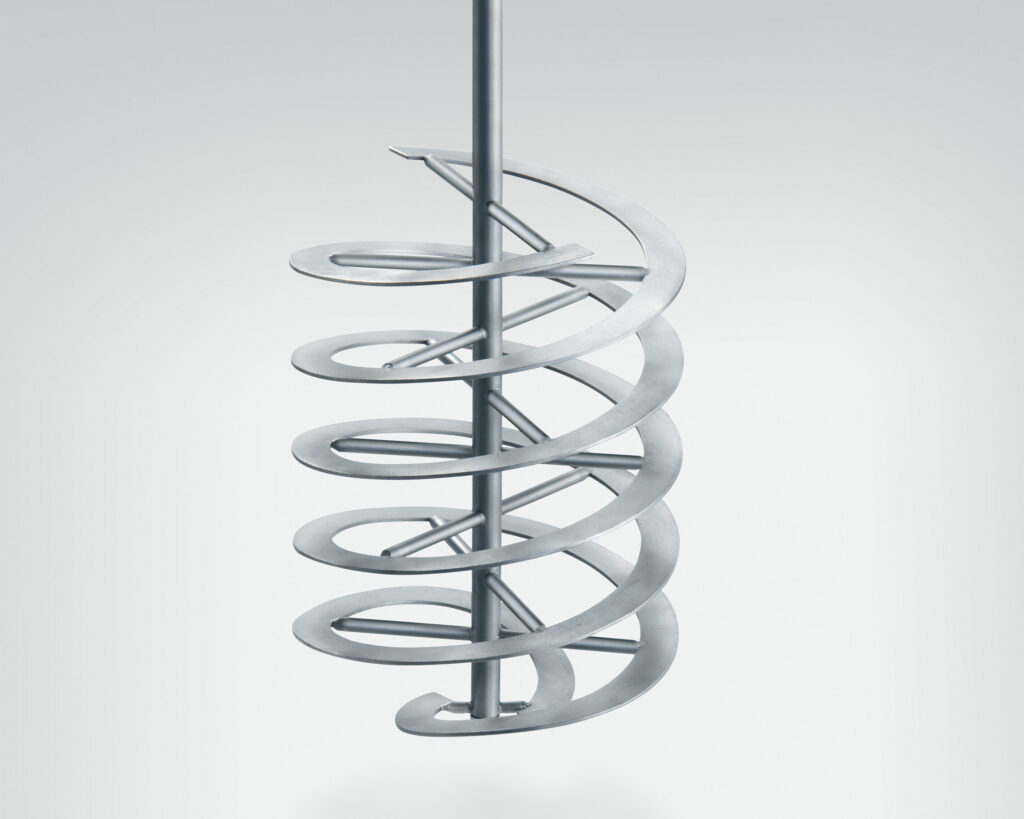

Reduced Maintenance Time: EKATO Lift and Swivel

The EKATO lifting and swiveling device enables a quick, easy and safe seal change during a maintenance interval. It is available for agitators up to size 220 and can of course also be retrofitted to existing HWL agitators.

The agitator seal can be exchanged without having to disassemble the complete agitator. This avoids long and therefore expensive downtimes as well as the use of heavy and dangerous equipment, such as e.g. cranes.

In combination with the EKATO shaft suspension device, seals can be exchanged without having to enter the tank! The suspension device secures the shaft at the mounting flange and prevents it from having to be supported with a scaffold. Please see our video showing the detailed functional principle of the features. Convince yourself!

EKATO Agitators HWL-N Lift and Swivel Mechanical seal removal instructions (to the top)